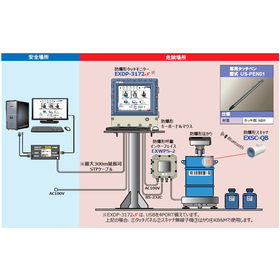

Explosion-proof weighing interface for paint mixing 'EXWPS-2'

Explosion-proof interface for collecting measurement data at hazardous material manufacturing locations.

In the paint industry’s mixing process, accurate formulation and a safe working environment are essential. Particularly in sites handling flammable substances, the accuracy of weighing data and explosion-proof performance are critical. Inaccurate measurements can lead to a decline in product quality and increased costs, while inadequate explosion-proof measures can result in serious accidents. Our explosion-proof weighing interface, 'EXWPS-2', enables the collection of weighing data in hazardous material manufacturing locations, supporting safe and efficient mixing operations. 【Usage Scenarios】 - Paint formulation process - Manufacturing sites handling hazardous materials - Collection of weighing data in explosion-proof areas 【Benefits of Implementation】 - Improved accuracy of weighing data - Enhanced work efficiency - Increased safety

basic information

【Features】 - Explosion-proof weighing scale power box made explosion-proof - Direct collection of weighing data from explosion-proof sites via RS232C/wired LAN/wireless LAN - Compatible with the FZ series from Shin-Etsu Chemical - Compatible with the KL-IS series from Kubota - Up to two explosion-proof scales can be connected 【Our Strengths】 Asahi Kasei Engineering Corporation provides comprehensive engineering services from design and construction to maintenance, offering optimal solutions tailored to our customers' needs.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Asahi Kasei Engineering Corporation is a company that conducts design, procurement, and construction (EPC) with an eye toward maintenance, and also proposes appropriate maintenance based on design data. In addition to maintenance, it is also possible to propose information systems that consider production efficiency and production losses. In terms of maintenance, we are developing equipment diagnostic devices that utilize digital technology.