Medical-grade transparent silicone tube for medical device manufacturing

Supporting medical settings with clear visibility.

In the medical device manufacturing industry, the reliability of catheters is crucial to ensure both patient safety and the efficient work of healthcare professionals. This is especially true in situations where accurate delivery of bodily fluids or medications is required, making the visibility of the contents essential. Inappropriate catheters can increase the risk of incorrect administration and infections. Our medical-grade transparent silicone tubes ensure visibility of the contents, enhancing safety in medical settings. 【Usage Scenarios】 - Infusion lines - Suction tubes - Drains 【Benefits of Implementation】 - Easier confirmation of contents, leading to improved safety - Increased work efficiency for healthcare professionals - Compliance with medical-grade and food sanitation law standards for peace of mind

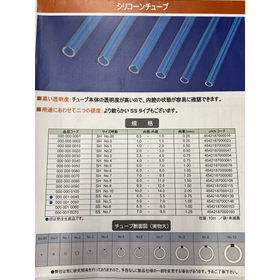

basic information

【Features】 - High transparency, excellent visibility of contents - Compliant with medical-grade and food sanitation law standards - Flexible and adaptable to various shapes - Usable across a wide temperature range - Two hardness options available to suit different applications 【Our Strengths】 Aizu Rubber Industry is your go-to for rubber and plastic resin molding. We offer ultra-fast and high-quality service from mold production to product delivery that cannot be matched elsewhere. We have a system in place to timely propose the most suitable products tailored to our customers' needs, along with logistical support. For custom-made products that fall outside standard specifications, we can provide full customization from design to manufacturing and shipping.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

Usage in the medical and nursing fields Fluid discharge and injection: The high transparency makes it easy to check the condition of fluids in the tube (color, turbidity, bubbles, etc.), thereby enhancing safety in medical settings. Food hygiene and manufacturing fields • Liquid food filling lines: Filling operations can be performed while monitoring the flow of juices, sauces, and other liquids. • Manufacturing processes requiring hygiene management: Silicone is sometimes treated as a material compliant with food hygiene laws, allowing for safe use. Samples are also available, so please feel free to contact us.

Recommended products

Distributors

Aizu Rubber Industry is a research and development, design manufacturing, and proposal sales company. Since our establishment in 1970, we have consistently responded to the needs of the dental and general medical device markets, as well as industrial rubber products, from prototype to mass production, including plastic and metal products. As a proposal-oriented trading company, we offer a wide range of products and flexible suggestions, from parts and components to machinery and equipment. We have established a system in collaboration with numerous partner manufacturers to timely propose optimal products that meet our customers' needs, along with logistical support. Particularly for custom-made products that fall outside standard specifications, we can provide full customization from design to manufacturing and shipping through collaboration with our own factory and partner manufacturers. Please let us know your inquiry, and we will provide you with proposals and estimates. We are also available for consultations and meetings in person, so please feel free to contact us.