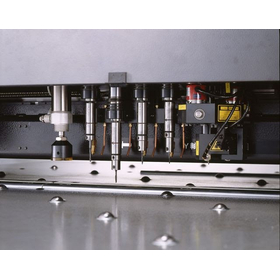

Network-compatible NC tapping machine 'CTS-900NT'

A network-compatible tapping machine that dramatically improves work efficiency by reducing processing time and setup time.

The network-compatible tapping machine 'CTS-900NT' enables multi-machine operation with NCT and laser systems. As a dedicated tapping machine, it contributes to improving the operating rate and productivity of blank process composite machines by enhancing the efficiency of tapping operations. With centralized data management, information retrieval is conducted swiftly, and it also features functions such as automatic program creation and processing path optimization. By confirming the hole positions of actual products before tapping operations following NCT and laser processing, it allows for set error checks and set misalignment corrections. 【Features】 ■ Auto programming ■ Processing history management ■ 4-axis tapper *For more details, please refer to the PDF document or feel free to contact us.

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

The Amada Group is a global manufacturer of metal processing machines that processes "metal sheets" and "metal blocks" to create metal products found in everyday life, as well as developing, manufacturing, selling, and providing services (operational guarantees) for peripheral equipment, molds, cutting tools, and software. The Amada Group consists of 93 companies, including its holding company, Amada Co., Ltd., and focuses on five main businesses: sheet metal, fine welding, cutting, grinding machines, and press automation solutions, operating in over 100 countries. As a global manufacturer of metal processing machines, Amada promotes automation and digital transformation (DX) through total solutions that include not only processing machines but also peripheral equipment, control systems, and software, contributing to the advancement of manufacturing.