Remote monitoring of various factory equipment metrics in real time! *Consultations are currently being accepted.

Real-time remote monitoring of equipment values on the screen! We implement systems such as automatic alerts based on thresholds to achieve labor savings and quality improvement!

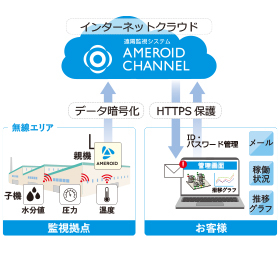

■Service Overview The remote monitoring system "AMEROID CHANNEL" by Ameroid is a cloud-based system that allows for real-time centralized management of equipment conditions within a factory. It instantly detects subtle changes and contributes to the prevention of potential troubles. There is no initial investment required, and we also provide a custom screen tailored for our customers. ■System Configuration and Communication Method - Information collected by sensors (subunits) attached to the equipment is received by the main unit. - Data is encrypted and transmitted to the cloud via 4G communication. - No installation work is required due to wireless communication. ■Security - The cloud is protected by HTTPS, ensuring high security. ■Real-Time Monitoring & Alert Function - Monitoring information can be checked anytime, 24/7, from a computer or smartphone. - An alert email is automatically sent when a pre-set threshold is exceeded. ■Graph Display & Report Generation - Measurement values are graphed, making it easy to intuitively grasp trends and patterns that may be difficult to see with numbers alone. - Regular reports and CSV output are utilized to support preventive maintenance and maintenance planning. ■Efficiency in Management - Centralized management of numerical data for all equipment. - Efficient maintenance based on data is possible.

basic information

It varies depending on the monitoring content, so please contact us for details.

Price information

It varies depending on the monitoring content, so please contact us for details.

Delivery Time

Model number/Brand name

Remote Monitoring System "AMEROID CHANNEL"

Applications/Examples of results

【Monitored Content】 ■Equipment Diagnosis Pressure, flow rate, vibration values, liquid volume, current values, power, etc. ■Liquid Condition pH, concentration, moisture content, oil content, kinematic viscosity, ISO grade, etc. ■Environment Temperature, humidity, CO₂ levels, CO levels, sound volume, etc. In addition to the above, we can suggest suitable sensors based on customer requests, so please feel free to consult with us. 【Case Study】 Here we introduce a case study of implementation in a coolant tank. ■Challenges Before Implementation pH and concentration were measured by taking samples of the coolant liquid on-site several times a day and using measuring instruments. Based on those values, adjustments were made manually by adding concentrated solution or water. ■Changes After Implementation By establishing a system to monitor pH and concentration 24/7 and automatically replenish concentrated solution or water based on those values, on-site work has been significantly reduced. Additionally, when values deviate from the standard, replenishment occurs immediately, bringing them back within threshold levels, which has also contributed to improved work quality. 【Information】 Ameloyd's remote monitoring system can monitor not only liquid purification devices but also the condition of your equipment and liquids. If you wonder, "Can we monitor this too?" please feel free to consult with us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Ameloid is a specialized manufacturer of liquid purification equipment, established in 1959. To meet a wide range of liquid processing needs, we have continuously developed and improved liquid purification technologies, refining various methods such as deep filtration, centrifugal separation, air drying, and vacuum distillation. We offer over 60 types of top-quality products specifically designed for liquid purification, including filters, centrifuges, oil-water separators, wastewater treatment systems, and chip dewatering systems, and we propose the optimal processing system based on the properties of the target liquid and the customer's application. In addition, we provide a variety of support plans, including trial plans, rental plans, and maintenance plans, to address concerns before implementation and support operations after installation. Under the slogan "Thinking of a Better Way," we continue to challenge ourselves as a group that constantly seeks "the best for our customers" without being satisfied with the status quo as a manufacturer of liquid purification equipment. We are committed to improving quality and reducing costs while contributing to the realization of our customers' sustainable production activities.