news list

1~16 item / All 16 items

-

Buehler promotes the scale-up of The Cultured Hub and cultured food.

Israeli cultured meat leader Aleph Farms will establish a production base in Kempthal, Switzerland. This initiative is based on a memorandum of understanding (MoU) with The Cultured Hub, a cultured food research facility established by Swiss retail giant Migros, the world's largest flavor manufacturer Givaudan, and Bühler, aimed at scaling up cultured food production. Under this MoU, Aleph Farms and The Cultured Hub will build a European production base for locally sourced cultured beef, enabling expansion into the European market with the approval of regulatory authorities. The Cultured Hub serves as a central facility that consolidates process development, sensor technology, scaling expertise, and access to partner networks for startup companies. Its technology partner, Bühler, provides strengths in bioprocess technology, automation, and high hygiene equipment design, facilitating the transition from pilot production to commercial production. This initiative strengthens the expanding food tech ecosystem, enhances the resilience of Switzerland's meat supply, and reaffirms our role in achieving sustainable food systems.

-

<Report on the Event> Buhler held the event "Buhler Networking Days 2025" to tackle sustainability challenges.

Bühler held the "Bühler Networking Days 2025" at its Swiss headquarters on June 23 and 24, 2025, aimed at sharing sustainability challenges and solutions. This fourth edition brought together over 1,200 leaders from various industries across more than 90 countries, including Japan. The event focused on the theme of "Realizing a business that sustainably supports 10 billion people by 2050," with the goal of spreading the ripple effects of already emerging solutions throughout society. During the second edition in 2019, Bühler announced its commitment to "reduce energy, waste, and water usage related to the customer value chain by 50% by 2025," investing approximately 500 million Swiss francs in research and development and creating new technologies and solutions across 15 value chains. As a result, not only has the company achieved significant reductions, but combinations with other companies' technologies have also enabled reductions of over 80% in environmental footprints. In terms of CO2e, the company anticipates potential reductions of several tens of percent across various industries related to its products, demonstrating the effectiveness of collaboration. The event concluded successfully with a speech of gratitude from CEO Schaefer.

-

Buehler achieves its 50th order for mega casting solutions for large cast structural components for automobiles.

Bühler Group announced that the cumulative orders for its mega casting solution "Carat" series, designed for large cast structural components, have reached 50 units. As major automotive manufacturers worldwide work on improving production efficiency and reducing weight for next-generation vehicles, the company's technology simplifies assembly processes and enables the integral molding of large parts, contributing to enhanced structural performance, productivity, and sustainability. The Carat series, with a clamping force of up to 92,000 kN, has been adopted by automotive manufacturers and OEM suppliers in Europe, North America, and Asia, and offers global service support, design and operational assistance from specialized teams, as well as continuous upgrades and optimization support. The equipment boasts high operational rates, low waste rates, and the capability for over 20 years of long-term operation, contributing to cost efficiency and reduced environmental impact. Leveraging the operational track record of approximately 1,000 Carat series units and nearly 100 years of die-casting experience, the company will continue to support new manufacturing in the automotive industry.

-

Bühler Naparost integrates technology to enhance sterilization processes for safe food processing.

The Beurer Group has announced the integration of steam and vacuum sterilization and roasting technology from Naparost AG (Switzerland). By adding Naparost's steam vacuum sterilization technology to our comprehensive product portfolio, we will become a unique one-stop solution provider in the nut processing sector. The company's sterilization technology demonstrates a high pathogen reduction effect of over 5 log for nuts, seeds, and low-moisture foods in general. It uses saturated steam to safely and effectively raise the surface temperature of products under partial vacuum, while also preserving quality, color, flavor, and texture. Additionally, we have fully renovated the Flavor Creation Research and Training Center at our Swiss headquarters, establishing a unique facility where the entire process, including sterilization equipment, can be tested and trained. We plan to begin trial operations at this center in August 2025, with the first special training session and facility opening scheduled for November.

-

Bühler Co., Ltd. has become a member of the Swiss Chamber of Commerce and Industry in Japan (SCCIJ).

In May 2025, Beurer Co., Ltd. became a member of the Swiss Chamber of Commerce and Industry in Japan (SCCIJ). The Swiss Chamber of Commerce and Industry in Japan (SCCIJ), established in 1981, plays an important role in strengthening economic relations between Switzerland and Japan. With around 200 member companies, including global multinational corporations, SCCIJ supports Swiss companies operating in Japan as well as Japanese companies interested in activities in Switzerland.

-

Groundbreaking ceremony for the Beuler Crushing and Dispersion Research & Training Center held in China.

Beurer held the groundbreaking ceremony for the "Crushing and Dispersion Research & Training Center" in Wuxi, China, on April 9, 2025. The center is scheduled to be completed in June 2026 and will serve as a hub for research and development as well as training in a wide range of fields, including innovations in inks and coating technologies, applications in pesticides and cosmetics, and next-generation battery materials. After the center's completion, it will strengthen the R&D framework within China and provide efficient and advanced technical solutions to local and international customers, achieving sustainable development and differentiation. The experimental plan includes water-based and solvent-based crushing and dispersion of inks, paints, and electronic materials, as well as the formulation of lithium-ion battery materials and slurries, and the fibrillation of dry electrodes. Additionally, it will support the evaluation and development of polymers, ceramics, and metal materials, as well as the testing of auxiliary equipment. Plans are also in place to introduce experimental powder mixers, vacuum degassing machines, homogenizers, and particle size distribution analyzers in the future. In terms of safety, workshops will be established to handle flammable and explosive chemicals, and a strict management system for exhaust gas, wastewater, and waste will be implemented. The center will also comply with local government safety and environmental regulations, contributing to the reduction of compliance risks.

-

Agreement on the supply contract for electrode slurry manufacturing machinery to FIB Corporation's lithium-ion battery production equipment.

We are pleased to announce that the Bühler Group has reached an agreement with FIB Company (Italy) regarding the supply of large-scale production equipment for lithium iron phosphate (LFP) batteries at their Teverola 2 plant. Our company plans to deliver a total of four continuous mixing lines for electrode slurry manufacturing, with two lines each for anodes and cathodes, expected to be installed by the end of 2025 and production to begin in 2026. These systems leverage our co-rotating twin-screw extrusion technology, consolidating multiple processes into a single continuous operation unit. This results in up to 25% lower energy consumption compared to traditional batch mixing methods and allows for operation with fewer operators. Additionally, the QuaLiB inline quality control system, equipped with sensors, data analytics, and automation features, enables precise monitoring of the manufacturing process, contributing to improvements in yield and cost.

-

Notice of Change in President

We would like to inform you that Mitsutaka Maeda has stepped down as President and Representative Director, and Benjamin Dupuy has been appointed as the new President and Representative Director.

-

Exhibited at Nano Tech 2025.

Bühler exhibited at the "nano tech 2025 International Nanotechnology Comprehensive Exhibition and Technical Conference" held at Tokyo Big Sight from January 29 (Wednesday) to January 31 (Friday), 2025. This was our first exhibition in five years, and we showcased a variety of wet grinding and dispersion equipment capable of handling diverse applications, including the compact modular wet grinding solution "SKID," which integrates pre-grinding and fine grinding, as well as solutions for inks, electronic materials, fine chemicals, and battery electrode slurries. Many people visited our booth, and on the final day, we held a seminar titled "Complete Continuous Production of [Lithium-Ion Battery] Electrode Slurry/Dry Electrodes," which concluded successfully. We sincerely thank everyone who attended.

-

Announcement of strategic collaboration with Mirapro Co., Ltd.

Our group company, Bühlert & Leibolt Optics (Germany), and Mirapro Co., Ltd. have announced a strategic collaboration. For more details, please check the related links below.

-

50th Anniversary Event of the Establishment of the Japanese Corporation

The Japanese subsidiary of the Bühler Group, which is headquartered in Switzerland and boasts a strong market share in the fields of food processing and chemical product manufacturing, Bühler Co., Ltd. (Headquarters: Yokohama City, Kanagawa Prefecture; Representative Director: Mitsutami Maeda), held a commemorative event for customers on November 19 at the Hotel New Otani to celebrate the 50th anniversary of its establishment in Japan. On that day, over 100 guests, including food manufacturers such as flour and confectionery producers, feed manufacturers, and ink and chemical-related companies that have supported Bühler's growth, were invited to a presentation and networking reception. From the Swiss headquarters, CEO Stefan Scheiber, Chairman of the Board Calvin Greider, and Karin Bühler from the founding family visited Japan, and they were joined by Roger Dubach, the Swiss Ambassador to Japan, to deepen ties with Japanese customers.

-

Established the "Insect Technology Center" to support the feed and food industry.

Bühler has established a world-class Insect Technology Center (ITC) at its headquarters in Switzerland. The ITC consolidates Bühler's expertise in the industrial use of insects and top-level infrastructure, allowing customers to conduct larval growth tests using various raw materials, develop product samples, evaluate breeding solutions, and receive training. Insects are gaining attention as a healthy and sustainable protein source for food and feed, and Bühler is working on the development of various technologies and services for the insect market, including the construction of industrial insect plants. With the establishment of the ITC, Bühler will further support the continuous development of the feed and food industries towards building sustainable food systems.

-

The UK's first full-scale gigafactory adopts Beuler's low-carbon battery mixing technology.

The Bühler Group, a pioneer in battery technology, announced that Britishvolt, which is constructing the UK's first battery gigafactory, has chosen Bühler's proven mixing technology for its battery manufacturing process. In line with Britishvolt's environmental, social, and governance (ESG) principles and commitments, this technology will achieve a 95% reduction in waste and a 50% reduction in energy consumption. The joint project with Britishvolt clearly demonstrates Bühler's strategy to develop and scale sustainable solutions for its customers. The battery slurry plant, with an annual production capacity of 20 gigawatt-hours (GWh), will achieve energy savings equivalent to the annual energy consumption of approximately 1,000 single-family homes through reduced land use and process efficiency. As e-mobility becomes a global megatrend, Britishvolt, which has set clear global goals, is making significant investments in building new production capacity. The Bühler Group will support the industry with solutions that enhance battery performance while making battery production more efficient and sustainable.

-

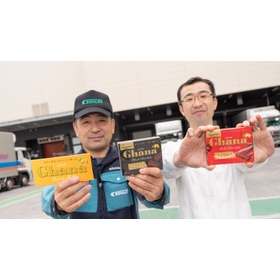

Introducing a large-scale retrofit case by LOTTE.

The Japanese chocolate manufacturer Lotte decided to refresh its production line by opting for a large-scale retrofit instead of investing in new equipment. This decision not only resulted in significant cost savings but also led to a reduction in energy consumption and a decrease in the environmental impact of its business activities, which has become a major advantage in today's circumstances. For more details, please refer to the related link.

-

The Protein Innovation Center was introduced in a business newsletter by JETRO (Japan External Trade Organization).

The Japan External Trade Organization (JETRO) has introduced the "Protein Innovation Center (PIC)," jointly operated by Bühler and Givaudan, on its overseas business information dissemination site "Business News." Opened in Singapore in April 2021, the PIC is a food lab equipped with state-of-the-art facilities. It provides startups, universities, and food manufacturers with the expertise, networks, and technology necessary to create plant-based alternative proteins. Customers can conduct trials of both high-moisture and low-moisture structured protein products using Bühler's twin-screw extruder located within the facility. In the Business News, an overview of the PIC and how to utilize it is provided, including an interview with Dr. Venkatesh, our Chief Innovation Officer. For more details, please visit the official JETRO website below. 【Business News】 30 companies, including Japanese firms, utilize the Protein Innovation Center to support plant-based meat development https://www.jetro.go.jp/biznews/2022/04/af12aeca378b6eb1.html

-

Jebodan and Bühler have established a 'Protein Innovation Center' in Singapore focused on plant-based foods.

The world-renowned flavor manufacturers Givaudan and Bühler jointly announced on April 26, 2021 (Singapore local time), the official opening of the APAC Protein Innovation Center within Givaudan's Singapore headquarters. The Protein Innovation Center is jointly operated by both companies and is connected to Bühler's R&D Innovation Center in Switzerland, as well as key regional hubs that enable plant-based product development on a global scale. By combining Bühler's extrusion processing technology with Givaudan's expertise in flavors, taste, ingredients, and product development, the center aims to collaborate with food processing companies, startups, and researchers from academic institutions in the Asia-Pacific region to develop and realize new plant-based foods that meet the taste, texture, and cooking methods demanded in Asia. The 400m2 facility includes a pilot-scale extruder, a state-of-the-art product development kitchen, storage facilities, and meeting rooms, as well as an area where visitors can observe live demonstrations.