Servo-type ultrasonic metal welder "MW-SERVO Series"

Severe pressure control can be easily achieved with our unique servo control technology!

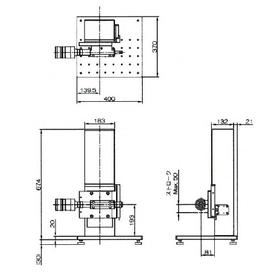

The "MW-SERVO Series" is an ultrasonic metal bonding machine that employs a servo motor in the pressurization mechanism, enabling ultra-precise control at the micron level. It achieves control resolution and repeatability that cannot be realized with air cylinders, making it ideal for bonding thin foils and delicate small parts. 【Features】 - Position control at the micron level during oscillation stop and cooling completion - Adjustable descent speed during oscillation - Amplitude switching function during oscillation - Maximum load of 4kN, suitable for applications requiring high loads such as copper wires and plates - In addition to position control, constant load control is also possible through torque control functionality *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Other Features】 ■ High-performance servo motor enables position control at the micron level ■ Various oscillation control modes - Time/Energy/Sinking dimension/Absolute dimension/Peak load ■ Horn descent speed can be freely set - Approach/Welding speed 1/Welding speed 2/Cooling/Horn ascent ■ Dimension measurement and feedback control using an external optical encoder mounted on the sliding part, achieving higher precision in position measurement ■ Horn standby position setting to minimize production tact during manufacturing ■ Torque control mode for constant load pressing, similar to a cylinder press *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Usage】 ■Joining thin foils and delicate small parts, etc. *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Cosmo System Co., Ltd. seeks infinite possibilities in plastic welding and metal welding, providing welding machines tailored to meet specific needs. We have formed a technical partnership with USA Sonics and independently develop and manufacture various welding devices, starting with plastic welding machines. We have established a test room to provide welding tests for various welding methods, technical comments, and data collection, where our specialized technicians will offer insights on welding shapes and methods suited to the welded products. With the slogan of always pursuing innovative ideas, we have consistently provided reliable equipment backed by proven results. If you have any issues in the fields of metal welding or plastic joining, please feel free to consult us.