Example 4: Preventing the contamination of molded products with dust by eliminating static electricity.

Improvement of troubles by eliminating static electricity from plastic injection molding machines.

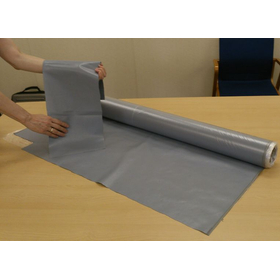

In plastic injection molding machines, when the molded product separates from the mold, it becomes charged with high voltage (10 kV to 50 kV) static electricity. This affects the work process and can lead to various troubles. By removing static electricity using the "Electro Mesh Method," the workflow can be improved, and productivity can be enhanced. For more details, please contact us or refer to the catalog.

basic information

【Overview】 ○ Preventing operator electric shock ○ Preventing the adhesion of "dust substances" to products ○ Preventing the re-adhesion of "burrs" ○ Electromesh curtain-type construction ○ The use of electro gloves is also effective ● For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

For more details, please contact us or refer to the catalog.

Related Videos

catalog(2)

Download All CatalogsRecommended products

Distributors

In December 1950, the company was established under the name Wako Electric Co., Ltd. in Akasaka Tango-cho, Minato-ku, Tokyo.