Example 5: Improving Fire Prevention Safety for Painting Conveyors

Continuous elimination of static electricity from painted parts by attaching "Electro Mesh."

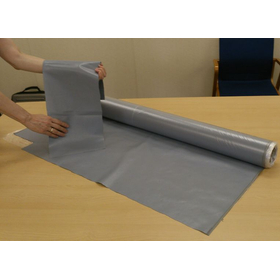

In gasket product painting factories, quick-drying paints are used to produce large quantities quickly. As a result, flammable gases can accumulate on the conveyor, and static electricity sparks may ignite the transported items. By installing "Electro Mesh" to eliminate static electricity, ignition accidents can be prevented. For more details, please contact us or refer to the catalog.

basic information

【Overview】 ○Preventing ignition accidents in advance ○Prevention of static electricity sparks ○Improving safety through ignition prevention ○Installation of electro mesh ○Continuous elimination of static electricity from painted parts ●For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

For more details, please contact us or refer to the catalog.

Related Videos

catalog(2)

Download All CatalogsRecommended products

Distributors

In December 1950, the company was established under the name Wako Electric Co., Ltd. in Akasaka Tango-cho, Minato-ku, Tokyo.