Example 6: Electrostatic Prevention and Improvement of Working Environment in a Buffing and Polishing Factory

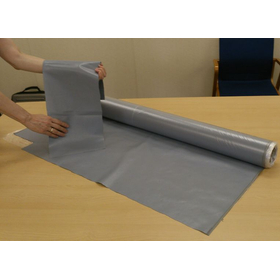

Complete prevention of static electricity using "electromesh" as a mat.

During the finishing polishing of molded products made of plastics, metals, wood, etc., static electricity with a voltage of 30KV to 70KV is generated due to the friction of the buff. By using "Electro Mesh" as a mat at the worker's position, static electricity can be completely prevented, resulting in a beautiful finish of the products and improved productivity. For more details, please contact us or refer to the catalog.

basic information

【Overview】 ○ Prevention of static electricity generation ○ Complete prevention of electric shocks during polishing ○ Improvement of the working environment ○ Use of electro mesh as a mat for static electricity prevention ○ Combination with electro gloves is also effective ● For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

For more details, please contact us or refer to the catalog.

Related Videos

catalog(2)

Download All CatalogsRecommended products

Distributors

In December 1950, the company was established under the name Wako Electric Co., Ltd. in Akasaka Tango-cho, Minato-ku, Tokyo.