Example 19: The electrostatic issues in the inspection process of a food can manufacturing factory can be improved.

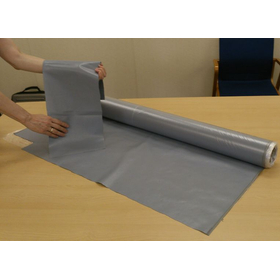

Improving static electricity issues with electro mesh electro gloves.

In the manufacturing factory for small metal cans for food, static electricity of over 40,000 volts often accumulates in the pre-process of product sampling inspection, which can cause the inspectors to experience electric shock. This can be completely improved with electro-mesh gloves, which also enhance productivity. For more details, please contact us or refer to the catalog.

basic information

【Overview】 ○ Improvement of static electricity issues ○ Removal of static electricity with electro mesh ○ Prevention of electric shock with electro mesh gloves ○ Elimination and removal of static electricity ○ Increase in productivity ● For more details, please contact us or refer to the catalog.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

For more details, please contact us or refer to the catalog.

Related Videos

catalog(2)

Download All CatalogsRecommended products

Distributors

In December 1950, the company was established under the name Wako Electric Co., Ltd. in Akasaka Tango-cho, Minato-ku, Tokyo.