Biodegradable ceramic angle joint gasket and packing compatible with RCF.

This is a gasket made with ceramic biodegradable fibers that complies with RCF regulations! (Exhaust gas stack, boiler system gaskets, packing)

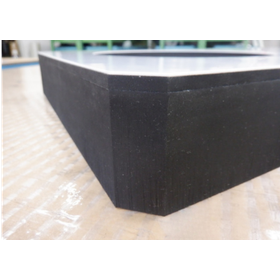

Refractory Ceramic Fiber (RCF regulations) has been implemented, and regulations regarding the use of ceramic fibers have been established. Our company has transitioned from traditional ceramic fibers to biodegradable ceramic fibers that are designed to be soluble in the body if ingested, in order to comply with these regulations. 【Product Description】 This is a packing material made by weaving biodegradable ceramic fibers into a corner shape. It is used in exhaust ducts, boilers, combustion equipment, pumps, and more. - This packing is woven with biodegradable fibers and organic fibers, complying with RCF regulations. - It does not have airtightness, so some leakage may occur. Please use it in areas where leakage is acceptable. - We also offer cut sales starting from a standard length of 30 meters.

basic information

Sealing and insulation of exhaust ducts, boilers, combustion equipment, pumps, manholes, and various flange sections.

Price range

Delivery Time

Applications/Examples of results

Sealing and insulation of exhaust ducts, boilers, combustion equipment, pumps, manholes, and various flange parts.

catalog(14)

Download All Catalogs

News about this product(1)

Recommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'