Insulation material "MG Board"

Excellent insulation contributes significantly to energy efficiency! It also has excellent heat resistance.

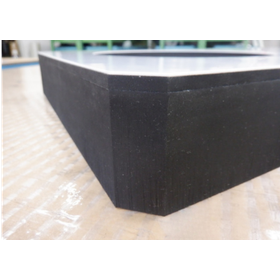

The "MG Board" is an insulation material that excels in thermal insulation and sound absorption. It is made by adding heat-curing resin as a binder to rock wool and forming it into board shapes, available in JIS grades 1 to 3. Additionally, the surface material of MG Board 080 is treated with ALGC (aluminum glass cloth). 【Features】 ■ Excellent thermal insulation and sound absorption ■ Lightweight and highly flexible, making it easy to handle and process ■ Excellent heat resistance ■ Greatly contributes to energy conservation due to its superior insulation properties ■ Designated as a recycling wide-area contractor *For more details, please download the PDF or feel free to contact us.

basic information

【Lineup】 ■080 ■080-ALGC ■120 ■150 ■200 *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'