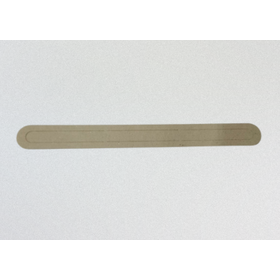

[Water Jet Processing Example] Gasket with Handle

We will introduce a case where having a handle made it easier to insert and position the gasket between the flanges!

We would like to introduce a processing case of "V6502 Black Super" conducted by Daiko Co., Ltd. Based on the customer's drawings, we manufactured a flange gasket for 10K-50A from a 3mm thick non-asbestos joint sheet "Vulcan No. V6502 (Black Super)." It was processed into a shape with handles using a water jet cutting machine. Having handles makes it easier to handle and manage the installation of the gasket. Additionally, since the handles protrude outside the flange, it helps prevent human error by forgetting to insert the gasket. [Case Overview] - Material: Vulcan No. V6502 (Black Super) - Product: Flange gasket for 10K-50A (with handles) - Work Details: Processed into a shape with handles using a water jet cutting machine *For more details, please download the PDF or feel free to contact us.

basic information

【Features of Processing】 ■ Improved workability ■ Prevention of forgetting to insert ■ Support for emergency items ■ Easy repeat ordering with data storage *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'