[Gasket Processing Example] TOMBO No.9007-SC

No need for a die for a medium lot of 500 pieces! We manufacture ring gaskets suitable for strong alkaline fluids.

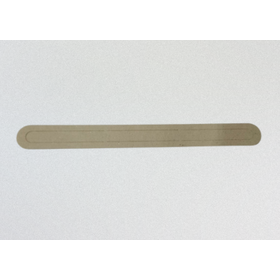

This is a case of producing 500 ring gaskets with an outer diameter of φ55mm and an inner diameter of φ43mm from the gasket sheet "TOMBO No.9007-SC," which is compatible with strong alkaline fluids. "TOMBO No.9007-SC" is a special gasket sheet made by blending carbon with PTFE (fluororesin). It exhibits excellent corrosion resistance against strong alkaline fluids such as sodium hydroxide and potassium hydroxide. Using our plotter processing machine, we were able to respond quickly to the production of 500 medium-lot items directly from CAD data without the need to create a die. [Case Overview] ■ Material: TOMBO No.9007-SC 1.5t ■ Size: Outer diameter φ55mm × Inner diameter φ43mm ■ Quantity: 500 pieces *For more details, please download the PDF or feel free to contact us.

basic information

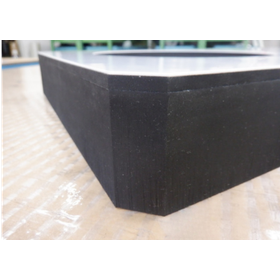

【Product Details】 ■ Suitable for strong alkalis: Exhibits excellent corrosion resistance against strong alkaline fluids such as sodium hydroxide and potassium hydroxide. ■ Wide range of applicable fluids: Can be widely used with water, steam, hot water, various gases (flammable, toxic, hydrogen, ammonia, oxygen, etc.), cryogenic fluids, and organic solvents. ■ Structure: By blending carbon fillers with a PTFE base, heat resistance and creep resistance are improved. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'