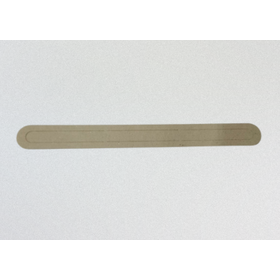

[Gasket Processing Example] Three Sheet 201S Ultra-Thin Frame Irregular Shape

Precision cutting of ultra-thin material with a thickness of 0.1mm! Create irregular frame shapes without the need for a die.

This is an example of producing a framed irregularly shaped gasket measuring 210mm x 355mm from the special sheet gasket "Three Sheet 201S" (thickness 0.1mm) manufactured by Three Bond Co., Ltd. The Three Sheet packing is a special gasket that combines the advantages of both solid sheet gaskets and liquid gaskets. It is impregnated with a unique viscous material in long and strong fibrous materials, providing flexibility and excellent conformity to flange surfaces. The processing includes cutting the outer circumference and applying an R65 curve to the inner diameter. Using our plotter processing machine, we precisely cut the material according to the CAD data without damaging it. 【Case Overview】 ■ Material: Three Sheet 201S (0.1t) ■ Size: 210mm x 355mm ■ Processing Details: Outer circumference cut, R65 curve processing on the inner diameter *For more details, please download the PDF or feel free to contact us.

basic information

【Product Details】 ■Unique Structure: Long and strong fibrous material is impregnated with a unique viscous substance. It is characterized by its flexibility and excellent compatibility with flange surfaces. ■Excellent Oil Resistance: It has outstanding resistance, especially to oils, making it suitable for oil lines in engines, transmissions, and various industrial machinery. ■Wide Temperature Range: Usable in a wide temperature environment from -40°C to 150°C. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'