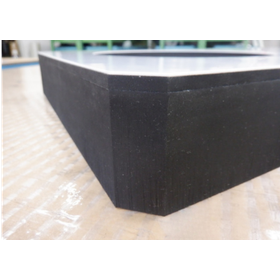

[Rubber Processing Example] CR Rubber Router Precision Machining, Counterboring, and Chamfering

Supports thick rubber with a thickness of 20mm! Achieved through machining with recessed holes and full C10 chamfering.

This is a case study of manufacturing block-shaped gaskets measuring 60mm × 95mm from 20mm thick CR rubber (chloroprene rubber). CR rubber is a rubber material that possesses a balanced combination of high weather resistance, heat resistance, oil resistance, and chemical resistance. Compared to other general-purpose rubbers, it has a low flammability characteristic (flame retardant). The processing details include counterboring to sink the heads of bolts and C10 chamfering around the entire product. Using our plotter processing machine (with router function), we minimized the distortion typical of thick rubber and achieved a sharp finish. [Case Overview] ■ Material: CR Rubber 20t ■ Size: 60mm × 95Lmm ■ Processing Details: Counterboring, C10 chamfering around the entire perimeter *For more details, please download the PDF or feel free to contact us.

basic information

【Product Details】 ■ Excellent Resistance: It possesses high levels of weather resistance, heat resistance, oil resistance, and chemical resistance, demonstrating stable performance even in outdoor environments or areas where oil may splatter. ■ Flame Retardancy: It has a characteristic of being less flammable compared to other general-purpose rubbers (flame retardant). ■ Main Applications: It is actively used in a wide variety of fields where reliability is required, such as automotive parts, construction gaskets, wire coatings, and general industrial products. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'