Processing examples of glass cloth gaskets

Examples of processing glass cloth gaskets | Water jet processing for frames of different widths and inner/outer R shapes.

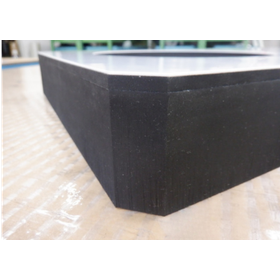

■Overview of Processing Example Product Name: Glass Cloth Gasket Dimensions: 4.8t × 140W × 180L Uneven Frame This example is a glass cloth gasket manufactured for flange parts of equipment. The design includes an uneven frame shape and specified inner and outer radii, with an emphasis on assembly compatibility and shape reproducibility. Water jet processing is used to minimize the processing difficulty inherent to fiber materials while achieving stable dimensional accuracy and finish.

basic information

■Product Features (Glass Cloth) D5400 is a gasket made by applying natural rubber to glass cloth and molding it into a specified shape. It has excellent thermal insulation properties and is environmentally friendly as it is non-asbestos. There are processing methods such as sewing, and it is capable of processing large diameters. It is used for high-temperature duct sealing. ■Processing Method (Water Jet Cutting) Water jet cutting is a water pressure cutting machine that uses high-pressure water to cut materials. It processes by spraying high-pressure water. The injection nozzle can be changed depending on the processing material, allowing for the production of high-quality products in a short time. Additionally, the dimensional tolerances that are typically achieved through manual processing are significantly improved, resulting in stable processing accuracy. The taper on the cut surface from press processing can also be improved with water jet cutting.

Price range

Delivery Time

Applications/Examples of results

■Q&A Q. Is it possible to achieve stable processing even with different widths and shapes? A. With water jet processing, we can handle designs with shape differences while maintaining uniform quality. Q. Do you have experience processing glass fiber materials? A. We have a track record in various applications such as equipment and ducts, and we manufacture with processing conditions that consider material characteristics. Q. Is it possible to consult from the drawing stage? A. Yes. We also accommodate preliminary consultations that include material selection and shape considerations. ■Daiko's Capability In gasket processing that includes complex shapes and specified radii, we can propose processing solutions that accurately reflect the design intent. We flexibly accommodate everything from prototypes to small lots and custom shapes.

catalog(2)

Download All CatalogsRecommended products

Distributors

Daiko is a manufacturer specialized in processing various industrial products, including gaskets and packing. With industry-leading processing equipment, including one of Japan's largest water jet cutting machines, and a wide range of materials such as joint sheets, rubber, resin, and metal, we meet our customers' diverse needs. Leveraging the technology and experience we have cultivated over 50 years, we provide high-quality, short-lead-time, and low-cost products to contribute to solving our customers' challenges. To respond to our customers' varied needs, Daiko's production bases are equipped with various processing facilities. Among them, the water jet cutting machines, with a total of four installed at our Osaka headquarters and Tokyo branch, boast one of the largest scales in the country. The maximum processing range is W4,000 × L5,500 mm, allowing for the high-precision manufacturing of large-diameter gaskets and packing. By maximizing material efficiency, we achieve the provision of 'high quality at low cost.'