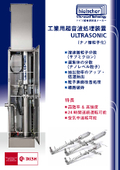

Ultrasonic dispersion [Hielscher] explosion-proof production type Japan model certification 8000W

Obtained domestic explosion-proof type number for production ultrasonic equipment for use in explosion-proof areas. Capable of large processing from 2000W to a maximum of 8000W with one unit.

Heelscher Co. has made it possible to safely use Heelscher ultrasonic processing equipment in explosion-proof areas by obtaining the explosion-proof type approval number in Japan. The type certification is for ultrasonic outputs of <2000W>, <4000W>, <6000W>, and <8000W>, and it seems to be for complete production facilities. Heelscher ultrasonic equipment, which guarantees high output and continuous operation for 24 hours, achieves what was impossible with ultrasonic devices through 100% cavitation erosion dispersion, differing from the dispersion methods used by shear force-based shear homogenizers, ultra-high pressure homogenizers, and stirring bead mills. Moreover, even with the same ultrasonic technology, the results are entirely different from those of immersion-type ultrasonic cleaners. This is a technology made possible only by Heelscher's powerful ultrasonic equipment, which features high amplitude and high surface strength. <Applications> Nanodispersion of aggregates, reduction of particle size, extraction, emulsification, dissolution, chemical reactions <Fields> Nanomaterials, batteries, electronic materials, coatings, inks, pigments, fuels, chemicals, cosmetics, biology, food & beverages.

basic information

This technology, which is distinct from the previously deemed impossible large-scale ultrasound, is a high-power model with a remarkable output. It is a dedicated model developed for mass production, capable of processing large volumes of liquid with an astonishing maximum output of 16,000W (UIP16000). Unlike other products, it does not require cooling of the equipment itself and can operate continuously for 24 hours. Multiple ultrasonic homogenizers can be used in parallel to meet the customer's output needs, and if necessary, it can be scaled up to a maximum of 120,000W (using 12 units of UIP10000).

Price range

Delivery Time

Model number/Brand name

Heelsher Ultrasonic Explosion-Proof Model EXDK2000

Applications/Examples of results

1. Ultrasonic Wet Dispersion 2. Ultrasonic Homogenization 3. Ultrasonic Particle Surface Functionalization 4. Ultrasonic Extraction and Cell Lysis 5. Ultrasonic Emulsification 6. Ultrasound for Chemical Activation 7. Ultrasonic Decomposition 8. Ultrasonic Particle Surface Cleaning 1-1 Nanomaterial Dispersion 1-2 CNT Dispersion 1-3 Graphene Oxide 1-4 Reinforced Rubber 2-1 Thermoelectric Nanopowder 2-2 Nanodiamond 2-3 Ultrasonic Dyeing 3-1 Mini Emulsion 3-2 Conductive Ink 4-1 NOx Reduction through Emulsification 4-2 Sonochemical Desulfurization 4-3 Biodiesel

catalog(3)

Download All CatalogsNews about this product(3)

-

[Ended] We will be exhibiting at Battery Japan 2022.

◆ We will showcase the "Powerful Ultrasonic Processing Device" by Heelsher for dispersing fine particles and nanoparticles in laboratory settings (100W) to production equipment (up to 16,000 W). 【New technology for contamination-free dispersion】【Japan Explosion-Proof Type Certification obtained (2000W-8000W)】【Guaranteed continuous operation 24 hours a day, 365 days a year】It is suitable for delicate dispersion due to 100% erosion dispersion by cavitation. ◆ We will also display a new technology for improving the hydrophilicity of powders, the "Ion Hydrophilization Device." Our booth number is E14-36. Please feel free to stop by.

-

Notice of participation in the International Nanotechnology Exhibition and Conference nano tech 2022 from January 26 (Wednesday) to January 28 (Friday), 2022.

DKSH Japan Co., Ltd. will be exhibiting at the nano tech 2022 International Nanotechnology Exhibition and Conference held at Tokyo Big Sight. At this exhibition, we will introduce the "ultrasonic processing equipment" that has obtained explosion-proof certification in Japan (Zone 1), as well as the bio-specific "Hielscher ultrasonic processing equipment," and the "powder ion hydrophilization device for nanoparticle pretreatment" and "slurry ion hydrophilicity enhancement device," as the exclusive distributor in Japan for the German ultrasonic equipment manufacturer "Hielscher Ultrasonics." We sincerely look forward to your visit. 【Exhibited Products】 ■ Powerful ultrasonic processing equipment / Ion hydrophilization device / Dispersion evaluation zeta potential meter

-

[Ended] [December 9 (Wed) - 11 (Fri), 2020] We will be exhibiting at nano tech 2021.

DKSH Japan Co., Ltd. will be exhibiting at nano tech 2021, the 20th International Nanotechnology Exhibition and Conference, held at Tokyo Big Sight (West Hall). This exhibition will showcase the latest technologies under the theme "Nanotechnology Supporting New Social Changes." This year, we will also have an online exhibition for customers who cannot attend in person. Exhibited product: Heelscher Ultrasonic Processing Device (Industrial and Laboratory Use) We sincerely look forward to your visit, either online or at our booth.

Recommended products

Distributors

DKSH is a member of the Swiss global company "DKSH Group." It provides comprehensive services and solutions across the entire value chain, combining procurement, marketing, sales, distribution, and after-sales service, through its three business divisions: consumer goods, production materials, and technology, with a long-term perspective.