Eddyfi ECTANE3 Electromagnetic Application Non-Destructive Testing Device

New model debut: Innovation in heat exchanger small tube inspection using the latest Remote Field Array (RFA) and AI-ECT!

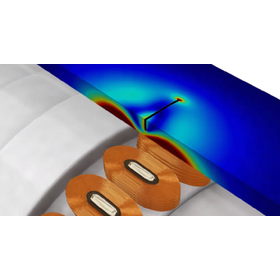

Ectane has over 1,000 delivery records spanning more than 10 years. The third-generation unit supports the tenth technology, Remote Field Array (RFA) technology, enabling advanced inspection of heat exchanger tubes. Unmatched Power and Flexibility Ectane is the world standard in electromagnetic application inspection of tubes and surfaces. This equipment offers a wide frequency range from 5 Hz to 10 MHz, 8 channel inputs, and up to 32 time slots, accommodating a broad range of applications. The modular design of Ectane 3 comes in 11 models, selectable to meet inspection needs, and is available in three different array configurations: 64 elements, 128 elements, and 256 elements, supporting 10 different inspection techniques. Wide Range of Applications Performs 10 types of inspection techniques: ECT, ECA, TECA, NFT, NFA, RFT, RFA, MFL, MFLA, IRIS. RFA, the Emergence of Advanced Inspection Technology The Remote Field Array (RFA) using a patent-pending low-frequency multiplexer is an inspection technology that only Ectane 3 can provide. It delivers high-resolution C-scan imaging for carbon steel tube heat exchanger inspections.

basic information

【Basic Features】 • Dimensions (H × W × D): 279.6 × 254.0 × 158.8 mm • Weight: 6.8 kg (with battery) • Enclosure Cooling: Sealed, fanless • Protection Rating: IP65 • Frequency: 5Hz - 10MHz • Array Connector: 160 pins • ECT (Extended)/RFA Connector: 41 pins • RFT/NFT/MFL Connector: 19 pins • ECT (Bobbin) Connector: 4 pins • I/O Connector: 18 pins • IRIS Connector: BNC Flexibility for Integration into Inspection Systems Ectane3 is an ideal system for automated inspection using ECA probes with robotic arms or crawlers. Multiple analog inputs and outputs are available to facilitate communication with PLCs. • Five TTL inputs for controlling remote data acquisition • 3-axis encoder input • Three relays to output system status • Real-time alarms and data streaming • Data acquisition software compatible with SDK

Price range

Delivery Time

Model number/Brand name

ECTANE3

Applications/Examples of results

Heat exchanger tube inspection (ECT, ECA, NFT, NFA, RFT, RFA, IRIS) Supports the majority of inspection methods, including the latest remote field array for magnetic tubes. Artificial intelligence-based tube inspection using Magnifi 5.x Through a process utilizing a patent-pending AI neural network, Magnifi enables the automatic detection of tube sheets, support plates, defects, etc., in heat exchanger ECT inspections. It aims to support higher quality data collection. Wide range of surface inspection capabilities • Detection and sizing of cracks in carbon steel welds (TECA) • Corrosion assessment of aluminum and stainless steel tank floors • Detection of stress corrosion cracking in base materials and high-precision depth evaluation • Surface inspection of various plant piping • Inspection of aircraft components • Surface inspection of railway axles

Detailed information

Related Videos

Line up(11)

| Model number | overview |

|---|---|

| ECTANE3-E | |

| ECTANE3-I | |

| ECTANE3-ERNM | |

| ECTANE3-ERNMI | |

| ECTANE3-E64RNM | |

| ECTANE3-E64RNMI | |

| ECTANE3-E128RNM | |

| ECTANE3-E128RNMI | |

| ECTANE3-E64 | |

| ECTANE3-E128 | |

| ECTANE3-E256 |

catalog(4)

Download All CatalogsNews about this product(4)

-

Application Note: Evaluation of Circumferential Cracking in Non-Magnetic Heat Exchanger Tubes - DefHi Probe [PDF Download Available]

Heat exchangers are used to heat and cool various fluids across a wide range of industrial sectors. This is particularly important for the power generation and petrochemical industries, where equipment reliability is of utmost importance. Standard ECT bobbin probes often struggle to detect circumferential cracks, posing challenges in many cases, but the DefHi probe offered by Eddyfi Technologies can identify various complex shapes inside heat exchanger tubes, allowing for the accurate detection of small circumferential cracks in the tube sheet, sizing, and evaluation of characteristics. Additionally, the inspection speed is eight times faster compared to rotating probes. The DefHi probe is less affected by changes in speed, making it usable regardless of the presence of a mechanical probe feeding device.

-

Application Note: DefHi ECA Probe for Defect Detection in Capacitor Fine Tube Welds [PDF Download Available]

Currently, seamless welded tubes are commonly used in capacitors. These tubes are prone to defects along the weld seam, such as axial cracks, blowholes, poor fusion, and inadequate melting. These defects make it difficult to achieve accurate sizing and classification assessments with standard eddy current bobbin probes. The reason is that the bobbin coil provides an average response over 360°, and the proportion of the weld defects relative to the entire tube wall being inspected by the probe is very small. To address this issue, Eddyfi Technologies has developed the "DefHi Probe," an eddy current array probe that uses multiplexing.

-

Application Note: Detection of Cracks and Corrosion in Aircraft Longeron [PDF Download Available]

Aircraft are the foundation of various industries and are subjected to harsh and nearly continuous use, making maintenance extremely important. Eddyfi Technologies has developed an ECA probe capable of inspecting both surface cracks and internal corrosion of multilayer aluminum in the longilon fastener section. For more detailed information, please contact us.

-

Application Note: Ensuring the Safety of Pressure Vessels with Shark Probes [PDF Download Available]

A pressure vessel is a sealed container designed to hold fluids at a pressure that is significantly different from the surrounding pressure. They are installed throughout refineries. Due to the importance of their function, pressure vessels must undergo rigorous safety inspections regularly. The Shark Probe manufactured by Eddyfi is specially designed to inspect weld line cracks on the surface of such equipment. The probe's spring-loaded fingers are designed to adapt to the shape of the weld reinforcement, allowing it to scan the reinforcement, toe, and heat-affected zone in a single pass. This probe is equipped with a built-in encoder, making it possible to accurately locate defects along the weld. For more detailed information, please contact us.

Distributors

Eddyfi Technologies contributes to improving productivity in manufacturing, various plants, and inspection service providers by offering the world's leading non-destructive testing (NDT) technologies, as well as promoting a safe society and environmental protection. The company focuses on providing advanced phased array ultrasound and eddy current array technologies, along with various ultrasonic and electromagnetic application technologies, including inspection equipment, sensors, software, and robots for key industries such as aerospace, energy, mining, power, and transportation. Eddyfi Technologies has over 650 employees across 13 centers of excellence (technology hubs) and sales offices worldwide, with NDT technology experts stationed at all locations.