Eddyfi Magnifi 5.0 ECT Data Acquisition and Analysis Software

Powerful. Efficient. Intuitive. Equipped with AI-ECT module.

For the past 10 years, the Magnifi software, which is a market leader with innovative and advanced features, has continued to empower non-destructive inspectors around the world. • Ready to use on-site A well-organized, easy setup workflow • High precision Automatically detects and marks signals for defects, tube sheets, and supports • Enjoy excellent data quality Verification and automatic screening of full-length tube inspection data • Quickly grasp critical indications Streamlined grouping of indications and tube classification features • Reduce the risk of missing defects An AI-based detection module that finds more indications An AI tool developed as an assist feature, ensuring analyst involvement and complete control

basic information

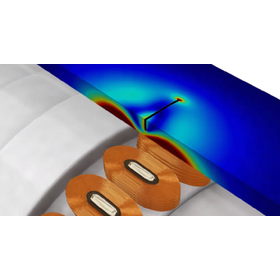

The Magnifi software, released in 2011, is used by thousands of operators worldwide for the inspection of various components. Since its initial version, it has integrated several technologies and has become more multifunctional over time. Magnifi allows the use of various tools to process source data: • 2D and 3D C-Scan • Real-time filters • Automatic threshold detection • Sizing curves, overlays • Superimposed channel display • Customizable information fields • Differential cursors, etc. Advanced signal processing Combined with industry-leading resolution probes, Magnifi has the capability to generate 2D and 3D C-Scans, enabling more intuitive result interpretation and data analysis. Latest technological innovations Magnifi 5 supports new technology specialized for the inspection of magnetic tubes, including Remote Field Array (RFA) and RFA probe products.

Price range

Delivery Time

Applications/Examples of results

Advanced Inspection of Heat Exchanger Tubes: • Eddy Current Testing (ECT), Eddy Current Array (ECA) • Near-Field Testing (NFT), Near-Field Array (NFA) • Remote Field Testing (RFT) • Magnetic Flux Leakage (MFL) • Immersion Ultrasonic Thickness Measurement (IRIS) Advanced Surface Inspection: • Eddy Current Array (ECA) • Tangential ECA (TECA TM) • Magnetic Flux Leakage Array (MFLA)

Detailed information

Related Videos

Line up(5)

| Model number | overview |

|---|---|

| STD version | The Magnifi Standard Desktop version (STD) supports up to 5 technologies in conventional mode: ECT, RFT, MFL, NFT, IRIS |

| PRO version | The Professional version (PRO) provides access to advanced inspections using array sensors ECA, TECA, MFLA, and NFA. |

| ACQ version | The Magnifi Acquisition (ACQ) license supports all the features necessary to maximize high-quality data for heat exchanger tube inspections using conventional technologies (ECT, RFT, NFT, MFL, IRIS). |

| GO version | Eddyfi Reddy operates with Magnifi GO, the embedded version of the Magnifi desktop. |

| CPN version | With Magnifi Companion (CPN), you can analyze any data acquired by the Reddy unit on the desktop. |

catalog(3)

Download All CatalogsNews about this product(4)

-

Application Note: Evaluation of Circumferential Cracking in Non-Magnetic Heat Exchanger Tubes - DefHi Probe [PDF Download Available]

Heat exchangers are used to heat and cool various fluids across a wide range of industrial sectors. This is particularly important for the power generation and petrochemical industries, where equipment reliability is of utmost importance. Standard ECT bobbin probes often struggle to detect circumferential cracks, posing challenges in many cases, but the DefHi probe offered by Eddyfi Technologies can identify various complex shapes inside heat exchanger tubes, allowing for the accurate detection of small circumferential cracks in the tube sheet, sizing, and evaluation of characteristics. Additionally, the inspection speed is eight times faster compared to rotating probes. The DefHi probe is less affected by changes in speed, making it usable regardless of the presence of a mechanical probe feeding device.

-

Application Note: DefHi ECA Probe for Defect Detection in Capacitor Fine Tube Welds [PDF Download Available]

Currently, seamless welded tubes are commonly used in capacitors. These tubes are prone to defects along the weld seam, such as axial cracks, blowholes, poor fusion, and inadequate melting. These defects make it difficult to achieve accurate sizing and classification assessments with standard eddy current bobbin probes. The reason is that the bobbin coil provides an average response over 360°, and the proportion of the weld defects relative to the entire tube wall being inspected by the probe is very small. To address this issue, Eddyfi Technologies has developed the "DefHi Probe," an eddy current array probe that uses multiplexing.

-

Application Note: Detection of Cracks and Corrosion in Aircraft Longeron [PDF Download Available]

Aircraft are the foundation of various industries and are subjected to harsh and nearly continuous use, making maintenance extremely important. Eddyfi Technologies has developed an ECA probe capable of inspecting both surface cracks and internal corrosion of multilayer aluminum in the longilon fastener section. For more detailed information, please contact us.

-

Application Note: Ensuring the Safety of Pressure Vessels with Shark Probes [PDF Download Available]

A pressure vessel is a sealed container designed to hold fluids at a pressure that is significantly different from the surrounding pressure. They are installed throughout refineries. Due to the importance of their function, pressure vessels must undergo rigorous safety inspections regularly. The Shark Probe manufactured by Eddyfi is specially designed to inspect weld line cracks on the surface of such equipment. The probe's spring-loaded fingers are designed to adapt to the shape of the weld reinforcement, allowing it to scan the reinforcement, toe, and heat-affected zone in a single pass. This probe is equipped with a built-in encoder, making it possible to accurately locate defects along the weld. For more detailed information, please contact us.

Distributors

Eddyfi Technologies contributes to improving productivity in manufacturing, various plants, and inspection service providers by offering the world's leading non-destructive testing (NDT) technologies, as well as promoting a safe society and environmental protection. The company focuses on providing advanced phased array ultrasound and eddy current array technologies, along with various ultrasonic and electromagnetic application technologies, including inspection equipment, sensors, software, and robots for key industries such as aerospace, energy, mining, power, and transportation. Eddyfi Technologies has over 650 employees across 13 centers of excellence (technology hubs) and sales offices worldwide, with NDT technology experts stationed at all locations.