Eddyfi Technologies ECT Probe for Small Tube Inspection

Global leader in eddy current testing, ECT probe for tube inspection by Eddyfi Technologies.

Non-destructive testing (NDT) of critical components is an essential technology for health and safety management in industries such as power generation, including nuclear, oil and gas, and aerospace. With world-class engineering, rapid production capabilities, and advanced inspection technology as our background, we provide our customers with advanced electromagnetic application inspection hardware and software that offer the highest performance and reliability, which are indispensable to their businesses.

basic information

Eddyfi manufactures and sells the following probes: - Standard bobbin probe - Removable bobbin probe - Flexible bobbin probe - Magnetic saturation bobbin probe - Probe for air conditioning units - DEFHI ECA probe - Single driver RFT probe - Single driver RFT flexible probe - Boiler single driver RFT probe - Dual driver RFT probe - Dual receiver RFT probe - Remote Field Array (RFA) probe - NFT probe - NFA probe - MFL probe - RFA probe - Internal rotating inspection probe (IRIS)

Price information

Please contact us.

Delivery Time

Model number/Brand name

Eddyfi Technologies ECT Probes

Applications/Examples of results

Wide range of surface inspection support • Detection and sizing of cracks in carbon steel welds (TECA) • Corrosion assessment of aluminum and stainless steel tank floors • Detection of stress corrosion cracking in base materials and high-precision depth evaluation • Surface inspection of various plant piping • Inspection of aircraft components • Surface inspection of railway axles

Detailed information

Related Videos

catalog(1)

Download All CatalogsNews about this product(2)

-

Application Note: Evaluation of Circumferential Cracking in Non-Magnetic Heat Exchanger Tubes - DefHi Probe [PDF Download Available]

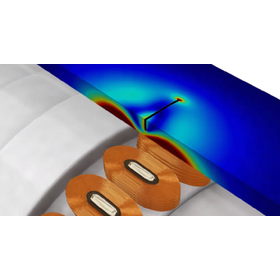

Heat exchangers are used to heat and cool various fluids across a wide range of industrial sectors. This is particularly important for the power generation and petrochemical industries, where equipment reliability is of utmost importance. Standard ECT bobbin probes often struggle to detect circumferential cracks, posing challenges in many cases, but the DefHi probe offered by Eddyfi Technologies can identify various complex shapes inside heat exchanger tubes, allowing for the accurate detection of small circumferential cracks in the tube sheet, sizing, and evaluation of characteristics. Additionally, the inspection speed is eight times faster compared to rotating probes. The DefHi probe is less affected by changes in speed, making it usable regardless of the presence of a mechanical probe feeding device.

-

Application Note: DefHi ECA Probe for Defect Detection in Capacitor Fine Tube Welds [PDF Download Available]

Currently, seamless welded tubes are commonly used in capacitors. These tubes are prone to defects along the weld seam, such as axial cracks, blowholes, poor fusion, and inadequate melting. These defects make it difficult to achieve accurate sizing and classification assessments with standard eddy current bobbin probes. The reason is that the bobbin coil provides an average response over 360°, and the proportion of the weld defects relative to the entire tube wall being inspected by the probe is very small. To address this issue, Eddyfi Technologies has developed the "DefHi Probe," an eddy current array probe that uses multiplexing.

Distributors

Eddyfi Technologies contributes to improving productivity in manufacturing, various plants, and inspection service providers by offering the world's leading non-destructive testing (NDT) technologies, as well as promoting a safe society and environmental protection. The company focuses on providing advanced phased array ultrasound and eddy current array technologies, along with various ultrasonic and electromagnetic application technologies, including inspection equipment, sensors, software, and robots for key industries such as aerospace, energy, mining, power, and transportation. Eddyfi Technologies has over 650 employees across 13 centers of excellence (technology hubs) and sales offices worldwide, with NDT technology experts stationed at all locations.