レーザ細孔加工機『DZ600』

レーザドリルは創造の領域へ。三菱電機の総合力による、新たなレーザ加工法

『DZ600』は、加工機構造の高剛性化により孔あけ加工の高速化と 高精度化を両立したレーザ細孔加工機です。 加工ヘッド側を両持ちガントリー構造を備えた直交3軸ワーク側を 回転2軸のロータリーテーブルで構成。 さらに細孔形成に特化した光学設計と三菱電機社製キーコンポーネントによる 高いビーム品質により高真円度、テーパの小さい孔あけ加工を実現します。 【特長】 ■同時5軸制御による3次元高速・高精度孔あけ ■孔あけ専用設計による高品質加工 ■三菱電機社製CWファイバレーザ発振器搭載による高信頼性 ■専用ソフトウェアによる簡単経路生成 ■コンパクト設計が実現する高い面積生産性 ※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

基本情報

【仕様(抜粋)】 ■形名:DZ600-F20 ■駆動方式(X×Y×Z,B×C):ACサーボモータ ■軸移動量(X×Y×Z):600×600×600mm ■軸移動量(B×C):±120×360deg ■工作物最大寸法 ・X,Y,Z 3軸使用時:500×500×500mm ・X,Y,Z,B,C 5軸使用時:Φ500×500mm ※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

価格帯

納期

用途/実績例

※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

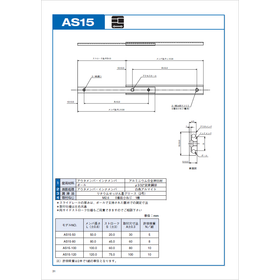

カタログ(1)

カタログをまとめてダウンロードおすすめ製品

取り扱い会社

当社は、1947年の創業以来、FA機器・動力伝導要品の総合商社として、一歩一歩実績を積み重ねて参りました。これは偏に皆様方のご支援の賜と深く感謝致しております。 ハイテク機械産業において、さらなる自動化・省力化・IT化など技術的要求は日々、高度化・多様化しています。このような状況の下、時代が求める工業要品をスピーディに調達し、供給責任を全うすることで世界のモノづくりに貢献することが、当社の使命と考えています。 これからも奉仕と誠実をモットーに、お客様のご期待・ご要望にお応えできる高付加価値なサービス提供に努めて参ります。何卒、今後ともご愛顧のほど、心からお願い申し上げます。