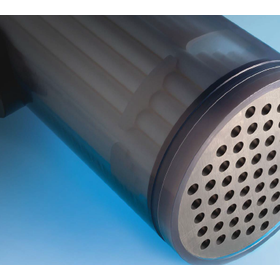

Global Filter's Polyether Sulfone GGPES Series

Achieve low pressure loss and long lifespan! Provides excellent flux density and low protein binding - Polyether sulfone 'GGPES Series General Grade'

The "GGPES Series General Grade" is a polyethersulfone filter cartridge suitable for cost-effective general membrane filtration. The high-retention polyethersulfone membrane provides excellent flux density and low protein binding. The inherently hydrophilic membrane easily wets, maximizing the use of the entire surface. It achieves low pressure loss and long lifespan compared to other products, and is designed to withstand repeated hot water sanitization and in-situ steam sterilization cycles. 【Features】 ■ Suitable for cost-effective general membrane filtration ■ Provides excellent flux density and low protein binding ■ Achieves low pressure loss and long lifespan ■ Designed to withstand repeated hot water sanitization and in-situ steam sterilization cycles ■ Manufactured in a cleanroom environment *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Operating Conditions】 ■Recommended exchange differential pressure: 35 PSID (2.4 bar) ■Maximum temperature: 176°F (80°C) ■Maximum differential pressure: 50 PSID (3.4 bar) @ 68°F (20°C) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Typical Applications】 ■ Deionized Water System ■ General Water Filtration ■ Liquid Clarification ■ Recirculating Liquid ■ Chemical Filtration *For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsRecommended products

Distributors

Following the establishment of our business foundation in Japan, we are actively working to expand and strengthen our business network in Asia to meet customer needs. As a result, we have become capable of supplying the excellent quality products of the Filtration Group not only to the Asian region but also to Europe and other areas. Furthermore, our technical centers in Asia, including Japan, provide customers with the best engineering solutions tailored to local needs.