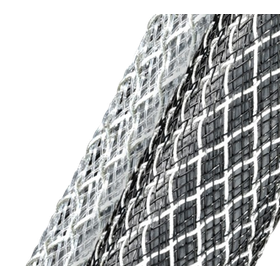

FEP fluoropolymer heat shrink tubing

Heat-shrinkable tube made of FEP with excellent heat resistance, cold resistance, and weather resistance.

■Features ● Excellent heat resistance, cold resistance, and weather resistance. Continuous use temperature for resin-free load FEP < -65℃ to +200℃ ● Inert to most chemical agents and solvents. ● Excellent weather resistance with no aging changes. ● Most substances are difficult to adhere to, and even if they do adhere, they can be easily removed. ● Non-combustible. ● Superior electrical properties. ■Color Translucent (natural color)

basic information

■ Processing Method ● Size Selection Please select based on the pre-shrink inner diameter and post-shrink inner diameter in the size chart. If the practical temperature is high, if there are sharp edges on the coated object, or if it is highly thermally conductive, please choose the largest size among the applicable sizes. ■ Made-to-Order Products Refer to the catalog and website. ● Cutting Cut the tube to a length that is approximately the same as the entire length of the coated object. ● Shrink Processing Temperature When performing shrink processing, set the temperature in the range of 100°C to 200°C, considering the heat resistance of the coated object, its shape, the shrink characteristics of the tube (melting point, shrink force, thermal conductivity, tensile strength at high temperatures), size, and workability. FEP heat shrink tubing begins to partially shrink at 80°C, shrinks almost completely at 150°C, and is fully shrunk at 175°C. By simply heating the tube to the shrink temperature, it adheres firmly to any shape of the coated object. Cautions 1. Heat and cool uniformly over the entire surface. 2. When coating long items such as rolls, heat from the center towards the ends, being careful to avoid air pockets. 3. Do not raise the temperature unnecessarily. ● Heating Equipment Refer to the catalog and website.

Price range

Delivery Time

Model number/Brand name

FEP fluoropolymer heat shrink tubing

Applications/Examples of results

■Purpose ● Protection coating for liquid transfer equipment, thermistors, and lead parts requiring chemical resistance and non-stick properties. ● Protection of microelements such as sensors. ● Non-stick treatment for rolls. ● Chemical-resistant protective coating for high-temperature applications. ● Coating for fiber protectors.

catalog(1)

Download All CatalogsRecommended products

Distributors

Hagitech Co., Ltd. is a pioneer in various types of tubes. We handle tubes made from all kinds of materials, including stainless steel, aluminum, titanium, copper, brass, iron, rubber, and plastic. If you have any inquiries such as "Can you make this type of tube?" or "I'm having trouble with this...", please feel free to contact us. Our company aims to continuously supply timely products that meet the needs of the times, such as "new products," "easy-to-use products," and "convenient products," through our website, with the goal of becoming a company that is helpful to society.