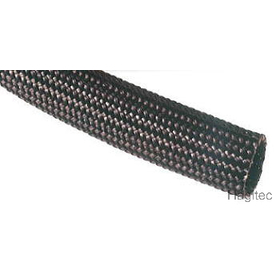

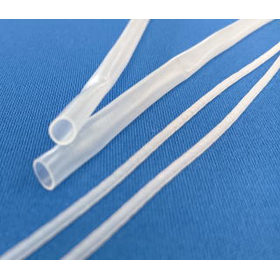

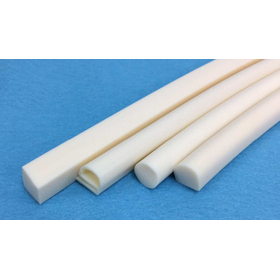

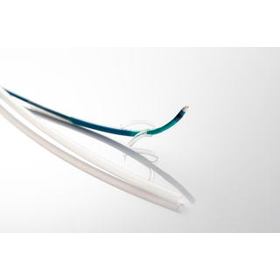

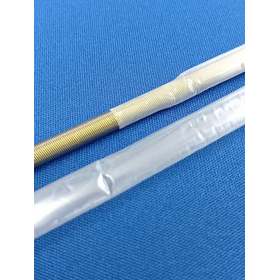

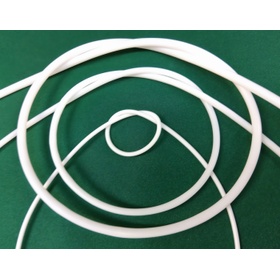

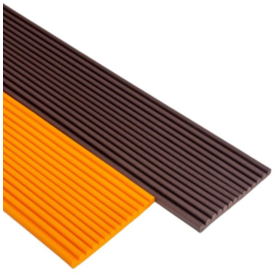

Katasumu resin tube (slit coil molded tube)

It is possible to manufacture large-diameter thin-walled tubes with a diameter of φ1 to φ250 using films such as polyimide and PPS. Prototyping in small quantities is possible.

Unlike extrusion molding technology, this is a tube made by slitting film materials such as polyimide, PPS, PEN, PET, PA, and PET, and forming them into coils with arbitrary inner diameters. We have production records for minimum inner diameters of φ0.8 to outer diameters of φ1, and up to a maximum of about φ250. The inner diameter can be set in units of 0.1mm, and lengths can be produced from 5 to 2000mm. The molding methods include bond molding using adhesives and ultrasonic welding. We can also propose multi-layer designs tailored to applications and environments using materials such as PI (heat-resistant up to about 350℃), PET (heat-resistant up to about 150℃), NOMEX (heat-resistant up to about 220℃), and PEN (heat-resistant up to about 180℃). - Bond Molding Using original bonds, we mold the tube. It excels in adhesion, heat resistance, and durability, allowing for the production of composite tubes made from different materials. The combination of materials is flexible. The heat resistance of the bond type depends on the heat resistance temperature of the adhesive. - Ultrasonic Molding This is a tube made without using adhesives, sealed by ultrasonic waves. It is molded using only a single material without employing different materials. This tube maximizes the properties of a single material.

basic information

●Production Achievement Materials PI (Polyimide), PEEK (Polyether Ether Ketone), PFA, FEP, PPS (Polyphenylene Sulfide), PA, PES (Polyether Sulfone), PEI (Polyether Imide), PET (Polyethylene Terephthalate), PEN (Polyethylene Naphthalate), PC, PE, PP, PS, PVC, NOMEX, Aramid, Aluminum Foil, Flame Retardant Paper, Various Non-woven Fabrics, etc.

Price range

Delivery Time

Applications/Examples of results

●Usage Record Mainly for insulation applications of wiring lead wires. Used in automotive-related fields for electric vehicles, hydrogen vehicle motors, and insulation of lead wires. Insulation applications for electrical equipment-related lead wires, such as in medical devices and home appliances like air conditioners and motors. Additionally, in aerospace applications, insulation that combines ultra-high temperature resistance. ●Materials, Heat Resistance (Reference Values), etc. - Polyimide, aluminum foil ~350℃, ultra heat-resistant, suitable for use in high-temperature environments such as space, artificial satellites, and electric vehicles. Can be set from an inner diameter of 0.8mm in increments of 0.1mm. - PPS, Nomex (flame-retardant paper) ~220℃, can be set from an inner diameter of about 0.8mm in increments of 0.1mm. - PEN ~180℃, for heavy electric motors, electric vehicles, medical applications, etc. Can be set from an inner diameter of about 0.8mm in increments of 0.1mm. - PET, PA ~120℃, for automobiles, various motor parts, etc. Can be set from an inner diameter of about 0.8mm in increments of 0.1mm.

catalog(1)

Download All CatalogsRecommended products

Distributors

Hagitech Co., Ltd. is a pioneer in various types of tubes. We handle tubes made from all kinds of materials, including stainless steel, aluminum, titanium, copper, brass, iron, rubber, and plastic. If you have any inquiries such as "Can you make this type of tube?" or "I'm having trouble with this...", please feel free to contact us. Our company aims to continuously supply timely products that meet the needs of the times, such as "new products," "easy-to-use products," and "convenient products," through our website, with the goal of becoming a company that is helpful to society.