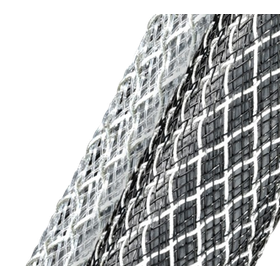

Chemical-resistant flexible fluorine sheet (porous PTFE + fluorine elastomer)

The chemical resistance is equivalent to perfluoroelastomer.

The chemical-resistant flexible fluorine sheet is an extremely thin rubber sheet that does not exist in conventional fluororubber (FKM) or perfluororubber (FFKM), which require chemical resistance and heat resistance. The chemical-resistant flexible fluorine sheet is a complete composite of porous PTFE and fluorine elastomer, making it a very stable product. It is suitable for applications that require durability and reliability.

basic information

- The chemical resistance is equivalent to perfluoroelastomer. - The operating temperature range is -50°C to 200°C. - It has a tear strength that is incomparable to conventional ultra-thin rubber sheets, preventing tearing from screw holes and the like. Therefore, it is also easy to handle. - The thickness precision is high, with a tolerance of ±7%. - Due to its cushioning properties, it does not exhibit the creep phenomenon (cold flow) that is a disadvantage of PTFE resin. Thus, it does not cause "drip leakage" and can be reused. - Because of its excellent chemical resistance, a significant extension of maintenance intervals is expected. - While it has flexibility, it also possesses the hardness of resin, making it resistant to deformation under pressure. - Machining from gaskets and cutting from sheets is also possible. - The price is less than half that of perfluoro rubber in sheet or gasket form. - Hardness: A75°±5° - FDA compliant product.

Price range

Delivery Time

Applications/Examples of results

- As a substitute for PTFE gaskets (soft Teflon, etc.). - Cushion rubber sheets that require chemical resistance. - Sealing materials related to semiconductor devices. - Release sheets for creating composite products with epoxy resin and FPC substrates. - Gaskets for fuel cells. - Pressure-sensitive membranes and protective films for sensor equipment. - Sealants and spacers for narrow areas that require cushioning.

catalog(1)

Download All CatalogsRecommended products

Distributors

Hagitech Co., Ltd. is a pioneer in various types of tubes. We handle tubes made from all kinds of materials, including stainless steel, aluminum, titanium, copper, brass, iron, rubber, and plastic. If you have any inquiries such as "Can you make this type of tube?" or "I'm having trouble with this...", please feel free to contact us. Our company aims to continuously supply timely products that meet the needs of the times, such as "new products," "easy-to-use products," and "convenient products," through our website, with the goal of becoming a company that is helpful to society.

![fefine[1].jpg](https://image.mono.ipros.com/public/product/image/5cd/2001518171/IPROS10594903808931453252.jpg?w=280&h=280)

![P1000273[1].jpg](https://image.mono.ipros.com/public/product/image_sub/5cd/2001518171/IPROS9414956644851437381.jpg?w=280&h=280)