[Technical Introduction] Holeless Metal Insert Molding

The range of use for exterior parts has significantly increased! Issues such as foreign matter contamination and tearing have been resolved!

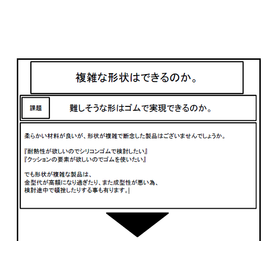

Our company offers "insert molding," where metal is fixed in a mold and surrounded by rubber to create a unified product. During the molding process, the rubber softens when heat is applied and flows within the mold, so it is necessary to secure the metal. This requires support pins, which leave holes in the final product. However, we have successfully performed insert molding without the need for support pins. Of course, we can maintain a consistent position for the inserted metal, allowing us to achieve insert molding even with metal spheres. The absence of holes for supporting the metal significantly expands the range of applications for exterior components. *For more details, please refer to the PDF document or feel free to contact us.*

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Boei Rubber is a trading company that deals with rubber, resin, and other materials. Utilizing the unique network of a trading company, we deliver products at reasonable prices and within short lead times. Even for difficult items, we leverage Boei Rubber's technology to produce and deliver them to our customers.