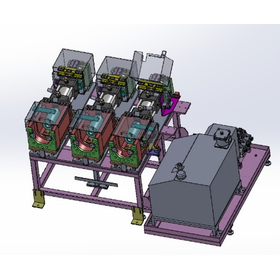

[Case Study] Pipe Terminal Processing Machine

An example of a processing machine that can shape with a thrust of about 100 tons through hydraulic drive for expansion and contraction of pipes!

We would like to introduce a case study of the "Pipe End Processing Machine" implemented at a pipe processing company. The customer requested, "We want production equipment that considers safety and workability. We need machines that ensure stable quality and are robust. We would like to be able to accommodate a variety of products by changing jigs and molds." In response, we produced the equipment in-house, achieving short delivery times and low costs. We received feedback that there were no machine troubles, the product quality was stable, and mass production was possible. 【Case Overview】 ■ Target Industries: Industrial machinery, automotive parts, special vehicles ■ Process: Pipe end processing ■ Reason for Selection: Custom-made to fit product sizes and shapes ■ Results and Effects of Implementation - No machine troubles, stable product quality, and capability for mass production - Highly rated, used in many locations both domestically and internationally *For more details, please download the PDF or feel free to contact us.

basic information

【Device Overview】 ■ We have a variety of specialized machines for processing and shaping pipe ends, including cutting, deburring, expanding, and reducing. ■ The expansion and reduction can be performed with approximately 100 tons of thrust using hydraulic drive. ■ It is also possible to design in combination with transport-related equipment. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(4)

Download All CatalogsRecommended products

Distributors

Our company is well-received by customers for our design, manufacturing, and sales of hydraulic devices and various specialized machines, focusing on automation and labor-saving solutions across a wide range of industries. We have also developed and manufactured unique products such as winching devices for fishing boats. Additionally, we are actively investing in new fields by developing civil engineering machinery speeders and washing machine spin drum processing machines for home appliance manufacturers.