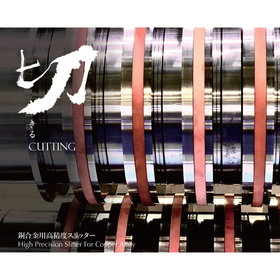

Free initial test cut available - Slitter that solves Bali issues

The "B-Cut Slitter" solves the "burr problem" for copper, iron, and stainless steel. It has demonstrated the highest level of cutting quality through test cuts on sheet materials.

The "B-Cut Slitter" is a high-precision slitter developed to minimize the occurrence of "burrs" (flashing), which has been a long-standing issue in the slitting processing of metal materials such as copper, iron, and stainless steel. It suppresses the generation of "burrs" to the utmost extent, contributing to quality stability in subsequent processes such as press processing. ■ Main compatible materials - Electronic components, automotive parts, precision equipment * Suitable for slitting processing of metal materials where the quality of the cut surface (smoothness) is required. ■ About the initial free test cut ▼ What is needed Sheet material you wish to cut ▼ Verification with sheet material Typically, long coil materials are required for slitter tests, but this machine can perform test cuts with "sheet materials (plate materials)." You can bring a small amount of your sample material to confirm the actual cutting quality. We are actively conducting demonstration experiments using test machines within our Kyoto headquarters factory to address concerns about whether "burrs really do not occur." * For details, please refer to the PDF data available by "downloading the catalog." * If you wish to request a test cut, please select "Request for test cut" from "Contact us via the web."

basic information

■Test Cut Specifications Material: Copper and Copper Alloys *Please consult for iron and stainless steel. Plate Thickness: 0.3mm to 4.5mm Plate Width: Max 650mm Length: 1000mm and above (sheet material)

Price range

Delivery Time

Applications/Examples of results

■Examples of Use Lead frame materials, connector materials, battery materials, precision spring materials, etc. ■Examples of Quality Improvement At a parts manufacturer where the yield in the next process was deteriorating due to burrs on the cutting surface with conventional machines, a test cut was conducted using this machine. By improving the cross-sectional quality, the quality issues caused by surface scratches from burrs have been resolved, leading to consideration for implementation. First, please verify the "burr-free" quality with your materials.

catalog(1)

Download All CatalogsRecommended products

Distributors

Our company is primarily a manufacturer of metal production equipment, focusing on copper and copper alloys. We also engage in contract manufacturing of metal-resin bonding lines for European factories by major domestic composite material manufacturers, as well as the design, manufacturing, and sales of research and development equipment for universities and research institutions, and industrial automation equipment. Additionally, we develop industrial software such as remote monitoring systems, and we also conduct prototype development, design, and manufacturing of roll levelers for various materials. Please feel free to contact us if you have any requests.