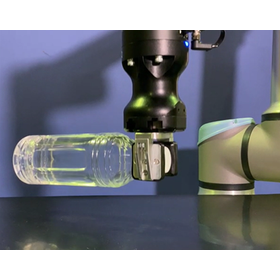

Space-saving and easily replicates the precision of skilled inspectors: 'KENTABLE-J'

Easy inspection for anyone by simply placing it in an optimized inspection environment♪

Visual inspection has transitioned from qualitative assessments by human eyes to quantitative assessments by inspection machines. 【Benefits of Introduction】 - Establishment of an optimized inspection environment - Product transportation is done manually, while inspection is automatically determined - Inspections can be easily performed even by those without expert skills - Improvement of manufacturing processes through the retention of inspection history - Reduction in capital investment costs ★ Easy operation for anyone from various settings to starting inspections Just press the operation button and set the inspection work! After that, KENTABLE-J automatically performs the pass/fail judgment. ★ One machine supports multiple product inspections! Typically, one inspection machine is required for each product type, which can lead to high capital investment costs. KENTABLE-J can accommodate multiple product types with just one machine, significantly reducing the introduction costs. *Up to 8 product types can be set.

basic information

Standard model, robot collaboration model, robot remote collaboration model, and slim model are available! For more details, please refer to the catalog.

Price range

Delivery Time

Applications/Examples of results

Medical industry: bottles, nozzles, caps, etc. Automotive industry: gears, motor housings, rubber caps, etc. Electrical and electronics industry: fittings, connectors, etc. Steel and metal industry: metal panels, shafts, etc.

catalog(2)

Download All CatalogsRecommended products

Distributors

Inaba Electric Industry Co., Ltd. Machinery Company - Three Business Areas 1) Robot and FA Business Robots are expected to automate the workplace, alleviate labor shortages, and stabilize quality. We propose a system of products, including not only collaborative robots that can be used without safety fences but also industrial robots and control devices that enhance productivity within factories. 2) FA Solution Business We provide comprehensive proposals that cover everything from software to hardware and networks, including "remote maintenance," "data collection," and "application development." 3) Original Product Development Business We are engaged in the development of products that enable the visualization of factories and the realization of smart factories through the use of IoT. We accurately capture the trends of the times and customer needs, and develop original products with high technical capabilities.