Stoga Corporation Flow Screw Fastening FSF Fastening Technical Documentation

Introduction of an innovative fastening method using a flood drill screw that perfectly finishes joining surfaces of multi-materials without damaging them.

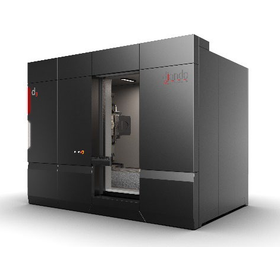

The fastening using Flow Drill Screws (FDS) is an innovative technology in dissimilar material joining, which has seen growing demand in recent years. The FDS screws are rapidly screwed into the workpiece while forming the flow drill funnel section, and then the screw itself is cut. The company manufactures FDS process units that include a screw driving system for FSF, an automatic supply system, and a control unit that manages and digitizes the entire screw fastening process. Stoeger’s FSF system is also ideal for use with robotic systems, allowing for quick bit changes and automatic unclamping and removal of the feed arm without any manual tools, making it very effective in automated production processes. The latest feature of Stoeger’s Flow Drill Screw, angle offset correction, can prevent corrosion that may occur if the surface of the battery case is damaged, making it suitable for fastening battery cases in EVs. *For more details, please download the PDF or contact us.*

basic information

For more details, please download the PDF or contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or contact us.