Andritz Schuler社 金型異物検知、保護装置

カメラベースのモニタリング装置で金型の損傷やプレスのダウンタイムを防止

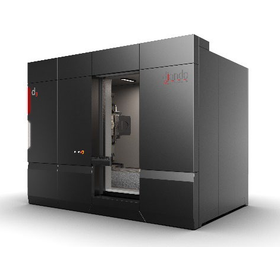

ビジュアルダイプロテクションは、生産稼働中の金型を保護します。カメラベースのこのシステムは、異物などの危険な状況をリアルタイムで検知し、金型が閉じる前にラインを停止させ、損傷を完全に防ぐことが可能です。これによりリスクを最小限に抑え、コストを削減します。ビジュアルダイプロテクションは多機能かつオープンなシステムなので、他社製のプレス機や他分野へも適用可能です。簡単に後付けができ、適用可能な範囲が広いため、ユーザー様は本システムをフレキシブルにご利用いただくことができます。トランスファープレスだけではなく順送金型ライン、ホットスタンプライン、樹脂成形や組み立てラインにも適用可能です。成形技術に限定されることなくシステムをご利用いただけます。

基本情報

・金型損傷の回避 ・部品ズレ検知 ・ラインの稼働率向上 ・供給能力の維持 ・簡単設置(設備停止時間 24 時間以内) ・金型 1 台につき最大 8 つのモニタリング作業 ・各用途に合わせた個別設定 ・迅速なセットアップと信頼性の高いモニタリング ・製品データセットの管理が容易 ・ユーザーグループで管理

価格帯

納期

型番・ブランド名

VDP

用途/実績例

・金型損傷予防 ・金型上の異物検知 ・部品位置ずれ検知 ・工程監視 ・生産、組立工程の最適化

関連動画

カタログ(1)

カタログをまとめてダウンロードおすすめ製品

取り扱い会社

株式会社イリスの歴史は1859年(安政6年)長崎・出島で始まりました。 福沢諭吉が辞書を買い求め、幕末諸藩や岩崎弥太郎が顧客名簿に名を連ねたユニークな外国商社は、常に革新的な技術を海外から紹介することで日本の近代化とものづくりに貢献し、イリスグループへと発展しました。 イリスグループは1898年に本社をドイツ・ハンブルクに移した後も、創業メンバーであるイリス家の5代にわたる経営のもと、変わらぬフロンティア精神をもって世界の技術サプライヤーを繋ぐ架け橋としてアジア市場を中心に活動しています。 株式会社イリスは、現在もイリスグループの重要拠点として印刷、紙加工、自動車、航空機、航空宇宙産業、食品、ゴム加工、X線透視・X線CT(Visiconsult社、diondo社)および品質保証システム、技術材料まで幅広い分野の技術製品とサービスを取り扱い、海外の新鋭の工作機械と技術を日本に紹介し、企業ユーザー向けプロジェクトマネジメントを専門的に提供しています。