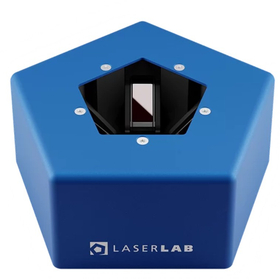

Robot Calibration System LaserLAB

Automatically perform rapid and high-precision robot calibration/correction.

In robots used in manufacturing sites, when calibration/correction of the robot becomes necessary due to parts replacement or collisions during maintenance, using Wiest's LaserLAB allows for automatic, rapid, and high-precision robot calibration/correction while keeping the robot installed on-site. This contributes to reducing downtime of the production line and labor hours due to robot stoppages.

basic information

Laser safety class: Class 2 according to DIN EN 60825-1:2015-07 Weight: 1.9 kg Size: 190 mm x 190 mm x 95 mm Normal battery operating time: 8 hours

Price range

Delivery Time

Model number/Brand name

Wiest AG

Applications/Examples of results

Application - Tool Calibration - Base Calibration - Cloning of Robot Cells - Robot Mastering - Multi-Robot Compensation - Protection of Production Lines - Virtual Commissioning

Related Videos

catalog(1)

Download All CatalogsRecommended products

Distributors

The history of Iris Co., Ltd. began in 1859 (the 6th year of the Ansei era) in Nagasaki's Dejima. A unique foreign trading company, which had customers such as Yukichi Fukuzawa who purchased dictionaries and various domains during the late Edo period, contributed to Japan's modernization and manufacturing by continuously introducing innovative technologies from abroad, eventually developing into the Iris Group. After relocating its headquarters to Hamburg, Germany, in 1898, the Iris Group has continued to operate under the management of the Iris family, spanning five generations of founding members, maintaining an unwavering frontier spirit as a bridge connecting global technology suppliers, primarily focusing on the Asian market. Iris Co., Ltd. remains a key hub of the Iris Group, handling a wide range of technical products and services across various fields, including printing, paper processing, automotive, aerospace, food, rubber processing, X-ray imaging and X-ray CT (Visiconsult and diondo), as well as quality assurance systems and technical materials. The company introduces cutting-edge overseas machine tools and technologies to Japan and specializes in providing project management for corporate users.