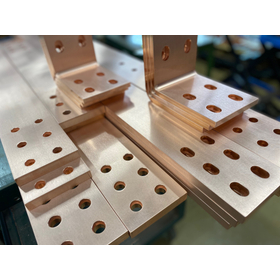

Copper busbar for transformers

Possible installation even in limited spaces with the bending processing of skilled craftsmanship!

Transformers and various panels differ in size depending on the installation location and the amount of power handled. However, the strength of electricity must not weaken. To maximize performance within limited constraints, we can bend and redirect the materials, and by processing as much as possible with a single copper busbar, we can minimize the installation process. It is possible to deliver stable electricity simply by securing it with screws! Given the rising prices of copper, we only charge for the necessary material costs plus processing fees, so please consider this!

basic information

Benefits of Using Copper in the Electrical Equipment Industry 1. Extremely high electrical conductivity 2. The material used in electrical equipment, C1100 (tough pitch copper), has a purity of 99.9% with almost no impurities, making it environmentally friendly 3. Traceability during material production is established, allowing for safe use 4. Recycling capability is inherently established For these reasons, it is used by transformer manufacturers and panel manufacturers.

Price range

P2

Delivery Time

P3

Applications/Examples of results

Copper parts for transformers and control panels

Related Videos

catalog(3)

Download All CatalogsRecommended products

Distributors

We have been providing copper components to transformer and control panel manufacturers, delivering energy through copper and ensuring safety and security for society. As a result of walking alongside our customers throughout this process, we have become a "copper specialty processing company"! When our customers are truly in need, we respond as quickly as the same day, embodying the spirit of mutual support! ■ Overwhelming inventory ■ Craftsmanship that allows for the fastest processing and youthful, energetic power ■ Strong network with local plating partner companies We can perform various processing methods such as machining, pressing, welding, and brazing. Since we have established a production system for a wide variety of small quantities, ■ Small lots ■ Various sizes ■ Complex shapes can also be handled quickly. We aim to be a company that delivers energy to everyone through copper, and we look forward to your continued support.