Technical Data: Welding Techniques for Copper and Their Selection

Challenges and Solutions in Copper Welding: The Importance of Technology Selection

"Challenges in Copper Welding: Precisely Because of Its High Thermal Conductivity" "Techniques for Welding Copper: Choosing the Right Method" "Key Points for Successful Copper Welding" *For more details, please refer to the PDF document or feel free to contact us.*

basic information

Welding copper can present challenges due to its excellent thermal and electrical conductivity. In spot welding, the ease of heat dissipation can lead to welding defects, but these challenges can be overcome with appropriate technology choices such as brazing or laser welding. Brazing allows for joining without melting the base material, while laser welding enables high-precision welding, although it is costly. The key to success is understanding the physical properties of copper and selecting the appropriate welding method accordingly. Special care is needed when welding copper alloys, as there is a risk of zinc evaporation, cracking, and blowholes. By choosing the right welding technique and managing the welding process, high-quality copper products can be manufactured. 'Challenges in Copper Welding: Precisely Because of High Thermal Conductivity' 'Technologies for Welding Copper: Choosing the Right Method' 'Key Points for Successful Copper Welding' *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

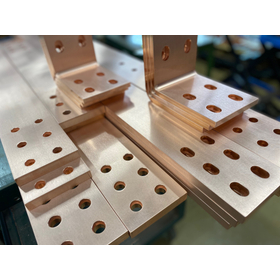

High-voltage distribution and receiving equipment - Large, medium, and small transformers - Control panels, receiving panels - Switchgear - Cubicles

Related Videos

catalog(4)

Download All CatalogsRecommended products

Distributors

We have been providing copper components to transformer and control panel manufacturers, delivering energy through copper and ensuring safety and security for society. As a result of walking alongside our customers throughout this process, we have become a "copper specialty processing company"! When our customers are truly in need, we respond as quickly as the same day, embodying the spirit of mutual support! ■ Overwhelming inventory ■ Craftsmanship that allows for the fastest processing and youthful, energetic power ■ Strong network with local plating partner companies We can perform various processing methods such as machining, pressing, welding, and brazing. Since we have established a production system for a wide variety of small quantities, ■ Small lots ■ Various sizes ■ Complex shapes can also be handled quickly. We aim to be a company that delivers energy to everyone through copper, and we look forward to your continued support.