[Case Study] Painting Factory

Introduction of case studies on lightweight to high-load conveyors for environmental conservation, low cost, high quality, and improved customer satisfaction!

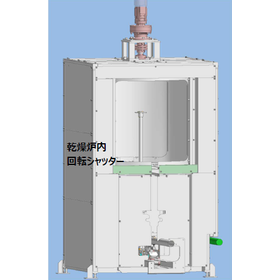

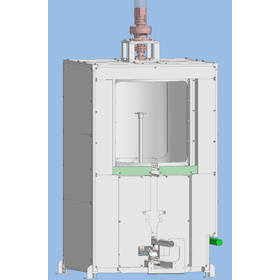

We would like to introduce examples of various Izutech products implemented in painting factories. We have introduced the floor fixed-pitch conveyor "FL-5," which has a proven track record in painting, assembly, and drying lines, as well as the "FLS," which excels in tact operation and fixed position stops. Additionally, we have implemented the fixed-pitch vertical conveyor "HL-5," which minimizes the installation area by installing the conveyor vertically. Furthermore, we have also introduced the overhead power & free conveyor "R&F," which uses a 3" rivetless chain. 【Implemented Products】 ■ Floor Fixed-Pitch Conveyor "FL-5" ■ Floor Power & Free Conveyor "FJ-II/FJ-III" ■ Floor Fixed-Pitch Conveyor "FLS" ■ Fixed-Pitch Vertical Conveyor "HL-5" ■ Overhead Power & Free Conveyor "R&F" *For more details, please download the PDF or feel free to contact us.

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

Detailed information

-

☆Quantifying shock to understand the destruction process. By implementing instrumentation, we can analyze the results of shock tests in greater detail. It is possible not only to quantify the tests but also to graph multiple test results for analysis. We can easily conduct comparative analysis by examining the differences in crack propagation and fracture speed for different materials when subjected to the same shock value.

-

☆Visualizing the differences in shock absorption. Even when the same shock is applied, the way materials respond to the impact can vary. For example, in a comparative test between materials A and B, A broke immediately after the impact, while B held on for a moment before breaking. Materials like A tend to leave sharp fracture surfaces, whereas B results in relatively smooth fracture surfaces. It has become clear that for products that are frequently handled by people, it is better to choose material B.

-

☆Observe impacts in detail through synchronized measurements with high-speed video! The speed at which materials reach fracture varies. For example, materials like carbon fiber reinforced plastic (CFRP) fracture at high speeds without bending, making them difficult to capture with the naked eye. By implementing instrumentation, in addition to high-speed video, you can obtain even more detailed data with a function that automatically tracks the crack tip.

catalog(1)

Download All CatalogsRecommended products

Distributors

Since our establishment, we have been a specialized manufacturer of material handling equipment centered around conveyors, and we have been widely supported by the industrial sector. With our long experience, we adhere to the motto of "accurately and swiftly applying specialized unique technology" and propose creative "material handling equipment that is friendly to people and the global environment" to our customers. Please feel free to contact us with any requests.