Copying process and trimming | Spray nozzle that is resistant to wear and has sharp cutting performance.

The "CP, CM, CTM" series is a spray nozzle that suppresses the adhesion of paper dust and maintains trimming accuracy with stable flow and pressure.

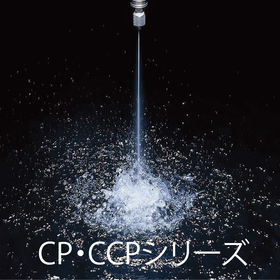

The "CP・CCP" series is a straight spray nozzle that injects the strongest straight jet flow, with a wide range of operating pressure and flow types, capable of accommodating various usage conditions. The "CP-STB" series is designed with a rectifier attached to the CP series, maintaining a stable straight jet flow even in curved piping where turbulence occurs. The "UT+CP" series features a ball joint attached to the CP series, allowing for adjustment of the spray direction up to 40 degrees, enabling fine-tuning of trimming position and angle. The "CM, CMP-T," "CM-FB," and "CTM" series have a body that separates the nozzle part from the strainer part, allowing for the replacement of the worn nozzle part. These nozzles have a nozzle tip made of ceramic (the CTM series uses carbide), which is resistant to wear and maintains performance over a long period. Additionally, the "CM-FB" series is designed to minimize the adhesion of paper dust to the nozzle body, featuring a small diameter and tapered shape, making it effective in environments troubled by paper dust. *Other spray nozzles are also available in a rich lineup. For quotes, custom orders, or any concerns regarding nozzles, please feel free to contact us. Phone and online consultations are also available at any time.*

basic information

*The spray volume, dimensions, and other specifications vary by model number. For details, please check the PDF materials or feel free to contact us.*

Price range

Delivery Time

Model number/Brand name

CP, CCP, CP-STB, UT+CP, CM, CTM, CM-FB, CMP-T, trimming nozzle

Applications/Examples of results

- Pulp and paper industry Trimming High-pressure washing of felts and screens - Food industry Cutting of food (such as tofu) Foam formation for beer (jet foamer) Cleaning of returnable boxes Cleaning of bottles - Others Cleaning of machine parts and localized cleaning Deburring

Related Videos

catalog(1)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

Leveraging our extensive experience and innovative spray technology cultivated over many years, we provide precise and high-performance solutions. With a unique approach that utilizes the power of mist, we support our customers' businesses to contribute to the efficiency of manufacturing sites, optimization of energy, and environmental protection. ■ Examples of Applications 【Electronics】Precision cleaning, etching, developing, humidification/cooling, static electricity prevention 【Pollution Control】Exhaust gas cooling, neutralization/cleaning, defoaming/deodorizing, dust removal, VOC suppression 【Steel & Non-ferrous】Cooling, scale removal, surface treatment, rust prevention 【Food】Cleaning, humidity control/cooling, disinfection, coating, fermentation promotion, moisture prevention 【Paper & Pulp】Cleaning, spraying, defoaming, trimming, wastewater treatment, humidity management 【Vehicles】Pre-paint humidification, cleaning/cooling, air blowing, rust prevention/dust removal 【Textiles】Humidification/cleaning, oiling, static electricity prevention 【Agriculture & Livestock】Watering, disinfection, pest control, germination promotion, temperature and humidity management 【Plastics & Rubber】Cooling, release, surface finishing, molding assistance 【Shipbuilding & Marine】Fire prevention, hull cleaning, corrosion prevention, rust prevention 【Medical & Pharmaceutical】Hygiene management, humidification, disinfection, clean room humidity management 【Mining】Dust suppression, humidity/cooling management, defoaming, etc.