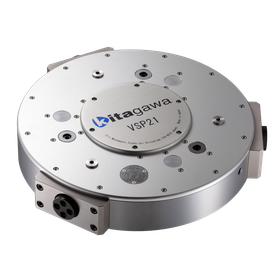

NC rotary table for grinding center

Demonstrates effectiveness in environments with dust, such as grinding processing, glass processing, and ceramic processing.

- Special seals and air purge shut out the intrusion of particles such as chips and grinding dust into the main body. - Purge structure with low air consumption (0.3L/min). - Low heat generation seal structure. - Long-lasting seals. - Structure that allows for easy cleaning and replacement of the seal area. - Compact body thickness. - Patent pending.

basic information

★Passed durability test of 1 million cycles in a slurry mixed with silicon carbide and alumina. * One cycle consists of forward rotation 180° → forward rotation 180° → reverse rotation 180° → reverse rotation 180°. ★Compatible NC rotary tables ・MR200, 250, 320 ・RK201 ・TR400 ・TT182, 200 ・RKT500 * Dimensions and specifications may differ from the base model. Please inquire at the time of your request. * Please contact us as the rotary joint may differ from the standard.

Price range

Delivery Time

Applications/Examples of results

Usable in dust environments such as grinding processing, glass processing, and ceramic processing.

catalog(1)

Download All CatalogsRecommended products

Distributors

Since our establishment in 1941, we have engraved our mission as a manufacturing company in our hearts and have been challenging ourselves in manufacturing and development. The environment surrounding businesses has always changed rapidly with the times, but the spirit of "monozukuri" (manufacturing) that we at Kitagawa have cherished from our founding to the present day remains unwavering and has been passed down through the ages. Through our manufacturing, we aim to gain even greater trust from our customers and to play a part in supporting the rich lives of people around the world. We will continue to take on new challenges in developing new products, new technologies, and high-quality services. We sincerely ask for your continued support and patronage in the future.