Adachi Heat Treatment Research Institute, Inc. - Business Introduction

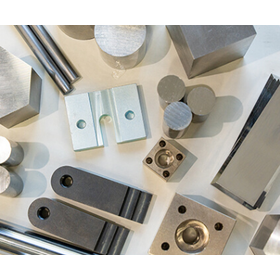

From large shapes to palm-sized small molds, leave the surface treatment to us!

Our company is capable of heat treatments such as vacuum hardening and vacuum annealing, as well as CVD-TiC coating, mirror polishing, and buff finishing. We also offer a wide range of heat treatments including solution heat treatment, aging hardening, precipitation hardening, and stress relief for aluminum alloys, and we can perform vacuum heat treatment for nickel superalloys (Inconel). Surface modification (shot peening, glass bead blasting, aerowrap) is also available. Through collaboration with partner manufacturers, we can provide high-frequency hardening, carburizing hardening, general PVD (TiN/TiCN/TiALN/CrN/DLC coatings, etc.), various plating options (hard chrome, electroless nickel, super corrosion-resistant, anodizing, Teflon, Nifgrip, etc.), WPC, isonite, nitriding, Teflon coating, and more. Because our company can perform a wide range of treatments, we receive many inquiries and requests for composite treatments (such as heat treatment + surface treatment or surface modification + surface treatment, etc.). We have developed CVD-SiC films and are receiving inquiries from industries related to lens molds and semiconductors. Additionally, we have developed an alternative treatment to salt bath hardening in vacuum heat treatment (currently applicable only to specific steel grades; other steel grades will be addressed through research and development).

basic information

**Capabilities** - General heat treatment (vacuum hardening, vacuum annealing, solution heat treatment, aging hardening treatment, precipitation hardening treatment, stress relief for aluminum alloys, vacuum heat treatment for nickel superalloys such as Inconel, etc.) - Mirror finishing and surface treatment pre-processing (buff finishing, shot peening, glass beads, aerolap) - CVD (Chemical Vapor Deposition) coating (TiC coating / SiC coating) - General PVD (Physical Vapor Deposition) (TiN / TiCN / TiALN / CrN / DLC / SiC, etc.) - High-performance plating (fluoropolymer plating, super corrosion-resistant nickel plating, wear-resistant electroless nickel, dry surface, full surface, PEEK coating, etc.)

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

Recommended products

Distributors

The Komaki New Industry Promotion Center was established with the aim of creating a sustainable foundation for industry, employment, and finance in Komaki City for the future. It is a new hub for industrial promotion in Komaki City, established to strongly support companies, primarily in the manufacturing sector. Additionally, we regularly hold seminars and workshops related to DX, IoT, RPA, beginner-friendly e-commerce, D2C, and more. We also welcome opinions and requests regarding seminar topics you would like to see held.