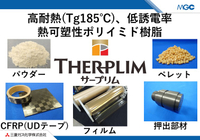

Thermoplastic polyimide resin Therplim powder filler application for toughness modifier in CFRP.

Improved toughness, enhanced sliding properties, and low dielectric effects from various powder additives! Introduction to powder filler applications.

Introducing the powder filler application of Therplim (filler). The effects of adding powder include improved heat resistance, enhanced mechanical properties, and improved sliding properties. For example, it provides toughness and reduces weight for high heat-resistant CFRP. 【Effects of Adding Powder】 ■ Improved heat resistance ■ Increased toughness ■ Enhanced mechanical properties ■ Improved sliding properties ■ Increased chemical resistance ■ Low dielectric * For more details, please refer to the PDF document or feel free to contact us.

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

[Research Examples of Other Fillers] ■ Heat-resistant fillers for resins (PP, PA) ■ Automotive and aircraft components ■ Industrial machinery ■ Alternative applications for PES, PA12, etc. * For more details, please refer to the PDF document or feel free to contact us. Shanghai Lingxiao Trading Co., Ltd. http://shryoyo.com/index.html

catalog(6)

Download All CatalogsRecommended products

Distributors

[Green Energy & Chemical Division] With the motto "Expanding in quantity overseas and expanding horizontally domestically," we aim to expand and strengthen our business foundation. For methanol, which is our main product, we will actively pursue overseas expansion while also developing life science product groups, enhancing MMA downstream, and expanding our catalyst business domestically.