Inkjet printer for print transfer sheets | For sewing and dyeing factories

<Sample products available> With DTF (Direct to Film) method, no plates! No pre-treatment! Improved production efficiency.

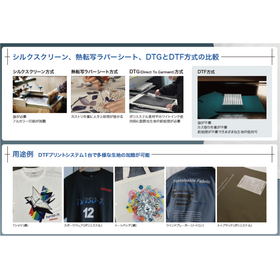

The DTF printer "TxF150-75" is an inkjet printer for print transfer sheets that brings together Mimaki's technology to solve common issues with DTF printers, such as "ink ejection failure" and "clogging of white ink." It is actively used in sewing factories and dyeing factories for printing on garments. 【What’s Amazing! Mimaki's DTF Printer】 - No need to prepare a plate for printing due to the DTF method. - Improvements in ink ejection failure and white ink clogging through a circulation function and degassed ink design. - With the nozzle recovery function, even if a nozzle is clogged, printing can continue without stopping work. - No need to prepare a plate for printing. - Reduction in labor costs as "casting" is unnecessary. - No pre-treatment of fabric is required. *For more details, please refer to the PDF materials or feel free to contact us. *We are offering free samples made with this product. Please indicate "Sample Request" in the purpose field when downloading the PDF or request it through contact.

basic information

<Product Specifications (Partial)> ■ Maximum Resolution: 1440dpi ■ Maximum Drawing Width: 800mm ■ Maximum Media Set Width: 810mm ■ Media Thickness: 1.0mm or less ■ Roll Weight: 45kg <About DTF Method> This printing method involves directly printing onto a special film called DTF film, sprinkling it with a powder known as hot melt powder, and then applying heat to create a dried transfer sheet. The resulting transfer sheet can be heat-pressed onto fabrics such as T-shirts. ⇒ There are many advantages to implementation, such as no need for preparing plates during printing and the ability for unmanned continuous operation.

Price range

Delivery Time

Applications/Examples of results

【Usage】 ■ Wear Print *For more details, please refer to the PDF document or feel free to contact us.

Related Videos

catalog(1)

Download All CatalogsRecommended products

Distributors

Mimaki Engineering is a development-oriented company that consistently engages in the development, manufacturing, sales, and maintenance services of industrial inkjet printers, cutting plotters, 3D printers, and more. Not only the printers themselves but also inks and software that add value to the printers are uniquely developed and provided as optimal solutions. As a market-oriented development company centered on inkjet and cutting technologies, we continuously offer "novelty and differentiation" in three markets: SG (Sign Graphics), IP (Industrial Products), and TA (Textile Apparel), while expanding our global sales activities. Furthermore, our company has consistently proposed standards of "speed" and "beauty" in the global sign graphics market and will contribute to the realization of small-lot, diverse production of industrial products and clothing through inkjet technology (i.e., digital on-demand production).