[Exhibition Special Page] Fine Cut Method

A cutting method that minimizes deformation (warping and burrs) during cutting and ensures high precision in length!

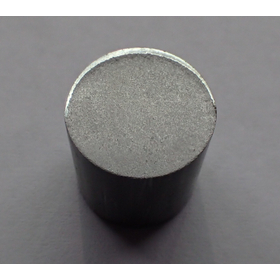

※Automotive World Nagoya 2025 Exhibition Content Our unique shearing technology allows for continuous and high-precision cutting from irregular coils. The flatness of the cutting surface is excellent, and the occurrence of warping and burrs is extremely low, which means that in some cases, the cut pieces can be used directly as components. 【What Fine Cut Can Achieve】 ◆ Process Simplification: Due to the superior flatness of the cutting surface, post-processing (barreling, machining) can be omitted or made more efficient. ◆ Continuous Production: High mass production capability through continuous cutting from coils. ◆ Dimensional Accuracy: - Minimal warping results in high length accuracy. - High length accuracy enables stable unit weights. *Examples of use: Slag, weights, etc. ◆ Method Switching: Achieves switching to fine cut for sintered parts, pressed parts, and former parts. *Alternative parts for sintering and pressing. ◆ Environmental Consideration: By achieving omissions and efficiency through process simplification, continuous production, and method switching, we can engage in environmentally conscious manufacturing.

basic information

■ Compatible Steel Types *Examples Mild Steel (SWRM, SWRCH) Structural Steel (SC) Hard Steel Wire (SWRH) Alloy Steel (SCM, SNCM) Bearing Steel (SUJ2) High-Speed Steel (SKH) Stainless Steel (SUS) Copper, Brass *For details, please contact us ■ Compatible Dimensions Cross-sectional Area: Maximum 200㎟ (Equivalent to φ16) Width: Maximum 25mm Length: 5–500mm *Depends on shape and steel type ■ Tolerances Length: ±0.05 *Depends on shape and steel type Burrs and Deformation (Contour Accuracy): ±0.05 *Depends on shape and steel type

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

For more details, please contact us.

Related Videos

catalog(1)

Download All CatalogsRecommended products

Distributors

Since its establishment in 1947, we have been manufacturing and selling steel wire products through drawing and rolling processes, and now we offer integrated production from cold-formed components to metal parts produced by pressing, shearing, and machining. In particular, we excel in the production of deformed coil wire with irregular cross-sections, and our strength lies in our ability to consistently produce unique deformed metal parts utilizing these irregular wires. Compared to powder sintering and precision casting methods used for manufacturing deformed parts, our deformed metal parts produced entirely through plastic processing at Namitei possess excellent toughness, strength, and smooth surface characteristics, making them widely adopted in sliding components and thin-walled deformed parts. To leverage the cost advantages of continuous processing, we propose specifications that mix functional applications and processing characteristics to meet our customers' needs.