Die Casting Aluminum Melt Plunger System MOHF (Mof)

Special resin adopted for the die casting plunger system * Suppresses galling and backflash within the sleeve due to high heat resistance and high durability.

Traditionally, the use of resin in the plunger system was unimaginable in the world of aluminum die casting. ~Part Characteristics~ 【Special Resin】 High heat resistance and durability suppress galling and backflash within the sleeve. 【Surface Treatment】 Special treatment retains lubricating oil, suppressing galling. 【Special Welding】 A special metal with low affinity for aluminum is coated (with a buildup process), suppressing aluminum melting. ~Effects~ * Prevention of chocolate stops due to galling suppression. * Extension of sleeve life due to backflash suppression. * High aluminum filling rate achieved through resin filling within the sleeve. * Suppression of aluminum temperature rise due to high thermal insulation. The structure is also very simple, reducing replacement effort (which is a welcome aspect for everyone on-site). The combination of part characteristics is flexible and can be customized according to user preferences. We kindly ask you to consider the new stance of the plunger system, 【MOHF】.

basic information

Main body: Made of special steel Sliding parts: Special resin and special surface treatment Biscuit section: Special welding The combination of each feature is flexible and customizable.

Price range

Delivery Time

Model number/Brand name

MOHF Plunger System

Applications/Examples of results

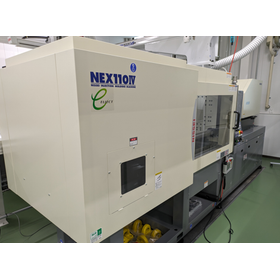

Plunger system for aluminum die casting machines

catalog(1)

Download All CatalogsRecommended products

Distributors

For the sake of our employees, our customers, our suppliers, and society, we express our gratitude for the company's development and will always remember to find joy in contributing to society while diligently working in our business.

![IMG_5741[1].JPG](https://image.mono.ipros.com/public/product/image/70d/2001509935/IPROS14327663168894883317.JPG?w=280&h=280)