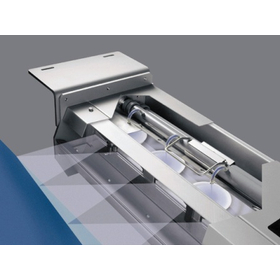

Liquid Coating Device WEKO Rotating Dumping

A liquid coating device that utilizes centrifugal force. Ideal for applying release silicone, anti-fog agents, and anti-static agents to various plastic sheets such as PET and PS!

The "WEKO Rotor Dumping" applies the coating liquid in a thin fan-shaped mist picked up by a rotor that rotates at high speed driven by a belt. The overall application width is determined by the number of rotors, the basic application amount is based on the rotor type, and the ON/OFF of the spray application is controlled by the opening and closing of a shutter. Features such as easy control of the application amount, quick responsiveness to changes in application amount, uniform application, and non-contact application have been well received, and it is widely used not only in Japan but also in many countries around the world for applying release silicone, anti-fog agents, and anti-static agents to plastic sheets. Additionally, due to unique features not found in other application devices, it is adopted in various industries beyond plastics, including paper, textiles, non-woven fabrics, and wood. For more details, please download the catalog or contact us. 【Exhibition Information】 ■Exhibition Name: High-Functionality Materials Week ■Date: November 12-14, 2025 ■Time: 10:00 AM - 6:00 PM ■Venue: Makuhari Messe ■Participation Fee: Free for pre-registered attendees ■Booth Number: 15-1 (Hall 3)

basic information

【Features】 ○ Very quick adjustment of application amount ○ Non-contact uniform application ○ Digital display of application amount allows for management of application quantity ○ A wide range of option settings according to purpose and application ○ Ability to set the application width relative to the sheet width ● For more details, please download the catalog or contact us.

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

【Applications】 ○ Coating of release silicone, anti-fog agents, and anti-static agents on various plastic sheets ○ Humidification and application of moisture agents in paper manufacturing and processing lines ○ Humidification, application of softeners, water repellents, and various resin processing agents in fiber processing lines ○ Coating of various functional agents such as oils, softeners, hydrophilic agents, and photocatalysts on non-woven fabrics ○ Humidification to prevent cracking and static electricity generation after drying in offset printing ○ Humidification in the board manufacturing process for particle boards, MDF, and others For more details, please contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

The Nikka Group is a flexible enterprise that selects options demanded by the times with unique ideas and shapes needs with reliable technical capabilities. Nikka's product offerings can be broadly categorized into two types: chemical products and machinery products. These soft and hard products are highly regarded in many industries, including printing companies and newspapers, boasting a dominant market share. To meet the diverse needs of customers in the printing industry, where high precision and high efficiency are required, Nikka will continue to provide total support from pre-press to post-press through the development and provision of equipment that is safe for people and friendly to the environment, based on 50 years of experience.