Blocking Prevention Powder - Nikkariko

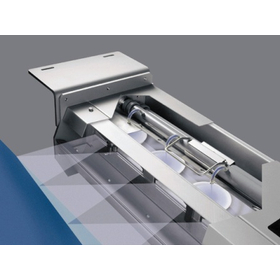

Industrial adhesive release agent to prevent adhesion of paper, film, and packaging.

Nikkariko is an industrial anti-adhesive agent that prevents printing and pressure-induced adhesion on paper, film, and packaging. - We offer a lineup tailored to various applications and needs. - It is a powder with stable quality. - It is a powder with high safety and minimal impact on the human body. 【Applications】 From thin paper to thick paper, film, laminate, packaging, etc. *For details, please inquire through a request for materials or download.

basic information

Nikkariko is an industrial anti-adhesion agent that prevents printing and pressure-induced adhesion on paper, film, and packaging. - We offer a lineup tailored to various applications and needs. - It is a powder with stable quality. - It is a powder with high safety and minimal impact on the human body. 【Applications】 From thin paper to thick paper, film, laminate, packaging, etc. *For more details, please inquire through a request for materials or download.

Price information

-

Delivery Time

Model number/Brand name

Nikkariko

Applications/Examples of results

Various industrial adhesive anti-block agents Prevention of adhesion in printed materials, ink offset, blocking, etc. Slip agents for laminating, improved opening properties during packaging, static electricity removal and prevention, etc.

catalog(1)

Download All CatalogsRecommended products

Distributors

The Nikka Group is a flexible enterprise that selects options demanded by the times with unique ideas and shapes needs with reliable technical capabilities. Nikka's product offerings can be broadly categorized into two types: chemical products and machinery products. These soft and hard products are highly regarded in many industries, including printing companies and newspapers, boasting a dominant market share. To meet the diverse needs of customers in the printing industry, where high precision and high efficiency are required, Nikka will continue to provide total support from pre-press to post-press through the development and provision of equipment that is safe for people and friendly to the environment, based on 50 years of experience.