news list

1~4 item / All 4 items

-

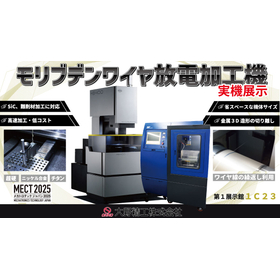

We will be exhibiting at MECT2025.

We will be exhibiting at MECT2025. 【Event Period】October 22 (Wednesday) to October 25 (Saturday), 2025 【Opening Hours】10:00 AM to 5:00 PM (until 4:00 PM on the last day) 【Location】Port Messe Nagoya 【Ono Seiko Booth Number】Exhibition Hall 1, C23 (Joint booth with Tainatech) 【Exhibits】 - Mo wire EDM machine HB series (live demonstration) - Ultra-compact Mo wire EDM machine TX150 (live demonstration) - Parallel positioning jig for wire cutting PAD series, etc. We will be demonstrating Mo wire EDM machines compatible with SiC and difficult-to-cut materials, so please stop by! Additionally, we will showcase the PAD series parallel positioning jig for wire cutting, which significantly reduces positioning time thanks to our unique patented technology. We invite you to see, touch, and experience our technology!

-

We will exhibit at MEX Kanazawa 2025.

We will be exhibiting at MEX Kanazawa 2025. 【Event Dates】May 15 (Thursday) - May 17 (Saturday), 2025 【Event Hours】10:00 AM - 5:00 PM (until 4:00 PM on the last day) 【Location】Ishikawa Prefectural Industrial Exhibition Hall 【Ono Seiko Booth Number】Hall 1, 022 【Exhibits】 - Mo wire EDM machine HB series (live demonstration) - Ultra-compact Mo wire EDM machine TX150 (live demonstration) - Parallel feeding jig for wire cutting PAD series, etc. We will be demonstrating Mo wire EDM machines that are compatible with SiC and difficult-to-cut materials, so please stop by! Additionally, we will showcase the PAD series parallel feeding jig for wire cutting, which significantly reduces the time for parallel feeding thanks to our unique patented technology. We invite you to see, touch, and experience our technology!

-

Start of handling pneumatic positioning jigs [ZERO-POINT SYSTEMS]. Significantly improves setup efficiency and achieves great results in the manufacturing field.

Our company, Ohno Seiko, has started handling the pneumatic positioning fixture "ZERO-POINT SYSTEMS." ZERO-POINT SYSTEMS is a positioning device mainly used in machining centers. By installing the main base in place of a vice on the machine, it allows for positioning at the same location consistently. The repeatability of positioning accuracy is excellent at 0.005mm, enabling continuous processing. The usage method involves first installing the main base on the machine. Next, prepare several set plates that match the main base. Set the workpiece on the set plates in a location away from the machine. Once the current product processing is completed, remove the set plate being processed and replace it with the pre-arranged set plate, allowing for a smooth transition to the next processing. It is said that the most time-consuming part of processing is the setup time. We hope that ZERO-POINT SYSTEMS can be utilized as a tool to reduce setup time for everyone.

-

It was published in the Daily Industrial News.

4/7 Nikkan Kogyo Shimbun An article about the PAD series has been published. Release of jigs for electric discharge machines to streamline horizontal adjustments. You can also read it in the electronic version below. https://www.nikkan.co.jp/articles/view/632919