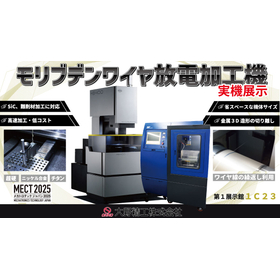

Ultra-Compact Molybdenum Wire Electrical Discharge Machine TX150

Utilize a small space effectively with a discharge machining tool the size of a tatami mat!

>>Features - A housing smaller than a tatami mat - Low cost due to the repeated use of molybdenum steel wire - Can be processed if it is a conductive material (such as carbide, nickel alloy, titanium, etc.) >>What is Molybdenum Wire? 1. By using molybdenum steel wire, which has excellent strength and toughness, in a wire electrical discharge machine, it enables the electrical discharge machining of "hard-to-machine materials." It can be processed if it is a conductive material. 2. Due to its strength and durability, it can be reused, allowing for lower operational costs compared to brass wire. It can also be used as a rough machining tool instead of a milling machine.

basic information

【Machine Specifications】 XY Axis Movement: 250mm × 150mm Maximum Processing Height: 250mm Workpiece Allowable Weight: 80kg Machine Installation Dimensions: W1400 × L700 × H1600mm Machine Body Weight: 800kg Wire Diameter: Φ0.18mm・Φ0.2mm

Price range

P6

Delivery Time

OTHER

Model number/Brand name

TX150

Applications/Examples of results

- Separation of metal 3D printed objects - Machining of difficult-to-cut materials - Rough machining

Detailed information

Line up(1)

| Model number | overview |

|---|---|

| TX150 | Machine installation dimensions: W1400×L700×H1600mm Machine body weight: 800kg |

catalog(1)

Download All CatalogsNews about this product(3)

-

We will be exhibiting at MECT2025.

We will be exhibiting at MECT2025. 【Event Period】October 22 (Wednesday) to October 25 (Saturday), 2025 【Opening Hours】10:00 AM to 5:00 PM (until 4:00 PM on the last day) 【Location】Port Messe Nagoya 【Ono Seiko Booth Number】Exhibition Hall 1, C23 (Joint booth with Tainatech) 【Exhibits】 - Mo wire EDM machine HB series (live demonstration) - Ultra-compact Mo wire EDM machine TX150 (live demonstration) - Parallel positioning jig for wire cutting PAD series, etc. We will be demonstrating Mo wire EDM machines compatible with SiC and difficult-to-cut materials, so please stop by! Additionally, we will showcase the PAD series parallel positioning jig for wire cutting, which significantly reduces positioning time thanks to our unique patented technology. We invite you to see, touch, and experience our technology!

-

We will exhibit at MEX Kanazawa 2025.

We will be exhibiting at MEX Kanazawa 2025. 【Event Dates】May 15 (Thursday) - May 17 (Saturday), 2025 【Event Hours】10:00 AM - 5:00 PM (until 4:00 PM on the last day) 【Location】Ishikawa Prefectural Industrial Exhibition Hall 【Ono Seiko Booth Number】Hall 1, 022 【Exhibits】 - Mo wire EDM machine HB series (live demonstration) - Ultra-compact Mo wire EDM machine TX150 (live demonstration) - Parallel feeding jig for wire cutting PAD series, etc. We will be demonstrating Mo wire EDM machines that are compatible with SiC and difficult-to-cut materials, so please stop by! Additionally, we will showcase the PAD series parallel feeding jig for wire cutting, which significantly reduces the time for parallel feeding thanks to our unique patented technology. We invite you to see, touch, and experience our technology!

-

We will be exhibiting at the 32nd Japan International Machine Tool Fair (JIMTOF2024).

We will be exhibiting at the "32nd Japan International Machine Tool Fair (JIMTOF2024)" held at Tokyo Big Sight from November 5 to 10, 2024. We will showcase the actual machines, including the CNC molybdenum wire EDM machines "HB400" and "TX-150," the leveling base for wire EDM machines "PAD series," and the pneumatic positioning fixture "ZERO-POINT SYSTEMS." This is a great opportunity to see the actual machines and products, so please come and visit us. 【Exhibited Products】 ◆ CNC Molybdenum Wire EDM Machine "HB Series" ◆ CNC Molybdenum Wire EDM Machine "TX-150" ◆ Fixture for Wire EDM Machines "PAD Series" ◆ Pneumatic Positioning Fixture "ZERO-POINT SYSTEM"

Recommended products

Distributors

At Ohno Seiko Co., Ltd., we primarily offer sales of electrical discharge machines, mirror finish processing, and precision parts processing. 【Sales of Molybdenum Wire Electrical Discharge Machines】 We have a business partnership with Suzhou Sanguang Technology Co., Ltd. We are the exclusive domestic distributor for the "HB Series" of molybdenum wire electrical discharge machines. Please feel free to contact us for test processing and other inquiries. 【Sales of Original Jigs】 We sell the "PAD Series" of parallel jigs for wire cutting, utilizing patented technology. 【Others】 - Sales of pneumatic positioning jigs, among others. 【Precision Parts Processing】 In a temperature-controlled room maintained at 20℃±1℃, we possess the latest three-dimensional measuring machines (three units), shape measuring instruments, tool microscopes, surface roughness measuring instruments, and more. We continue to challenge the limits of ultra-mirror finish processing with an Rz of 0.2μm and ultra-precision processing. Please feel free to contact us for prototypes and other requests.