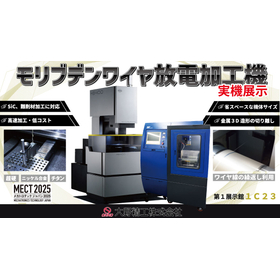

[MECT2025 Actual Machine Exhibition] Molybdenum Wire Electrical Discharge Machining Machine

[MECT2025 Live Demonstration] Electric discharge machine compatible with high-speed processing, difficult-to-cut materials, and SiC processing.

【Molybdenum Wire Electrical Discharge Machine】 HB Series <<Advantages of Molybdenum Wire Electrical Discharge Machines>> 1. Capable of processing difficult-to-cut materials 2. Cost reduction through the repeated use of molybdenum steel wire 3. Shortened work time due to high-speed processing Also compatible with processing compound semiconductor materials (SiC). By using high-strength and toughness molybdenum steel wire, we have enabled high-speed processing and the ability to handle difficult-to-cut materials. Until now, electrical discharge machining was considered to be time-consuming and costly, but the HB series achieves high-speed and low-cost processing by repeatedly using molybdenum steel wire that can withstand high currents. The processing fluid is sprayed, eliminating the need for ion exchange resins or water temperature management, resulting in a compact machine with very low power consumption. If you are considering reducing processing time and costs, please take a moment to consider us. 《Test processing and actual machine viewing are also possible, so feel free to contact us!♪》

basic information

- The wire is made of high-strength, high-toughness molybdenum steel wire. - The wire can be reused repeatedly for about 60 to 80 hours. - The processing fluid is sprayed (no ion exchange resin or large water tank required). - Creating programs is easy. - G-code is also acceptable. << About the Service >> A domestic service center is established in Aichi Prefecture. Free service support for one year. Consumables and maintenance parts are always in stock for immediate supply.

Price range

P6

Delivery Time

OTHER

About 3 months

Model number/Brand name

Molybdenum Wire Electrical Discharge Machine HB Series

Detailed information

-

<Repeated Use of Wire> By circulating the wire inside the machine and rotating the wire winding drum in both forward and reverse directions, it enables the same wire to be reused for extended periods. This also contributes to cost reduction of the wire. The drum can hold approximately 200 meters of wire, allowing for continuous processing for 60 to 80 hours under normal conditions.

-

<Usable Interface> Visualizes the processing status, allowing even beginners to easily maximize the machine's capabilities. Once used, processing data can be retrieved from the data bank for reuse.

-

Significant cost savings are possible because ion exchange resin and water temperature management are not required. A large water tank is also unnecessary, making it a compact and space-saving unit.

-

Examples of surface roughness based on the number of cuts (see image)

Related Videos

Line up(3)

| Model number | overview |

|---|---|

| HB400 | External dimensions: 2020×1700mm X・Y movement range: 400×300mm |

| HB600 | External dimensions: 2260×1870mm X・Y movement range: 600×400mm |

| HB800 | External dimensions: 2585×2535mm X・Y movement range: 800×600mm |

catalog(4)

Download All Catalogs

News about this product(1)

Recommended products

Distributors

At Ohno Seiko Co., Ltd., we primarily offer sales of electrical discharge machines, mirror finish processing, and precision parts processing. 【Sales of Molybdenum Wire Electrical Discharge Machines】 We have a business partnership with Suzhou Sanguang Technology Co., Ltd. We are the exclusive domestic distributor for the "HB Series" of molybdenum wire electrical discharge machines. Please feel free to contact us for test processing and other inquiries. 【Sales of Original Jigs】 We sell the "PAD Series" of parallel jigs for wire cutting, utilizing patented technology. 【Others】 - Sales of pneumatic positioning jigs, among others. 【Precision Parts Processing】 In a temperature-controlled room maintained at 20℃±1℃, we possess the latest three-dimensional measuring machines (three units), shape measuring instruments, tool microscopes, surface roughness measuring instruments, and more. We continue to challenge the limits of ultra-mirror finish processing with an Rz of 0.2μm and ultra-precision processing. Please feel free to contact us for prototypes and other requests.