[Application Example] Insulation related to powder manufacturing machinery and equipment

Large silo moisture-proof insulation heaters, suitable for dust collector hoppers, etc.! Customizable to fit your shape.

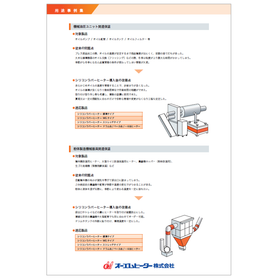

We would like to introduce a case where "silicone rubber heaters" were implemented for insulation related to powder manufacturing machinery and equipment. Due to issues such as "the bran from the brown rice milling machine becoming damp and clogging the discharge outlet" and "wanting to maintain a constant temperature when mixing powder and liquid, which varies with the seasons," this product was introduced. Heaters were installed on the back of discharge outlets and trays to prevent condensation, and they were also affixed to the outside of drums and tanks to maintain a constant environmental temperature. [Improvements after implementation] - Heaters were installed on the back of discharge outlets and trays to prevent condensation. - Custom orders can be made to fit complex shapes of dust collectors and large piping. - Heaters were affixed to the outside of drums and tanks to maintain a constant environmental temperature. *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Case Overview】 ■Target Products - Heater for moisture prevention in rice milling machines, large silo heaters for moisture insulation, dust collector hoppers (for powder moisture prevention), organic waste processors (for organic fermentation insulation), etc. ■Conventional Issues - The bran from automatic rice milling machines becomes damp and clogs the discharge outlet. - Dust collectors and piping for incinerated ash can become clogged due to seasonal and temperature changes. - When mixing powders and liquids, it is necessary to maintain a constant temperature that varies with the season. ■Applicable Products - Silicone rubber heaters: standard type, MG type, stretch type, drum can/pail can/one-gallon can heaters. *For more details, please refer to the PDF materials or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Our efforts with materials and our accumulated unique technology turn dreams into tangible forms. Silicone rubber heaters were born around 1965 during the development of rockets by NASA for their first moon landing. Our company recognized the potential of these heaters early on and has been working to promote their use by developing a manufacturing method that allows for production from a single unit. We are a specialized manufacturer of planar heating elements. We import materials from the UL-certified American company ARLON, and we appreciate your trust in our O&M silicone rubber heaters.