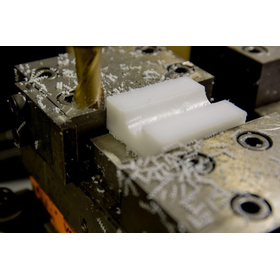

半導体検査治具向けポチコン板材

微細加工時に高精度な切削加工が容易に!ミクロ補強性により製品としての耐久性が向上

「半導体検査治具向けポチコン板材」は、ミクロ補強性・低摩耗性を 有しながら、微細加工性に優れた板材です。 微小径ドリルを用いて、加工が困難なΦ20µm&壁厚3µmの丸穴加工品が 可能。更に微小径エンドミルを用いて、30µmのリブが多く存在する 緻密な形状加工も容易となります。 また、小径ドリルで加工した場合、ポチコンIT6B板材は比較材と比べても、 穴の偏心量が小さくて位置精度が良好で、バリが少ないことも確認できました。 【特長】 ■微細加工性 ■良好な穴位置精度と低バリ性 ■微細加工品におけるミクロ補強性 ※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

基本情報

※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

価格帯

納期

用途/実績例

※詳しくはPDFをダウンロードしていただくか、お気軽にお問い合わせください。

関連動画

カタログ(1)

カタログをまとめてダウンロードこの製品に関するニュース(3)

-

KATACHIストーリー コラム:PEEK加工とは?基本特性から加工の注意点、選定ポイントまで徹底解説

大塚化学は、「KATACHIストーリー コラム記事の掲載」を開始いたしました。 コラム:「PEEK加工とは?基本特性から加工の注意点、選定ポイントまで徹底解説」 PEEKは、優れた耐熱性、耐薬品性、機械的強度から、医療、航空宇宙、半導体など多岐にわたる分野で採用が拡大しています。しかし、その高性能ゆえに加工が難しい側面もあり、精密な部品製造には高度な技術と専門知識が不可欠です。 この記事では、PEEK樹脂の基本特性から加工の注意点、最適な加工パートナー選定のポイントまで、製造業の皆様がPEEK加工を成功させるための情報をご紹介します。 詳しくは、関連リンク先より弊社HPのKATACHIストーリーをご覧ください。

-

KATACHIストーリー 第2回コラム:「スーパーエンプラ加工の基礎知識!用途・種類・耐熱温度など」

大塚化学は、「KATACHIストーリー コラム記事の掲載」を開始いたしました。 大塚化学は、これまで粉末状や液状等、部品になる前の「素材」を提供してきました。 これからは、素材の力と自社のコア技術を活用し、これまでの事業範囲を超えて新たな挑戦を続けています。 その一環として立ち上げられたのが「KATACHI Business」です。 単なる素材販売にとどまらず、素材を部品のような製品群としてKATACHIにすることで新たな価値を創造する。 この新たな取り組みを「KATACHI Business」と呼んでいます。 当社が推進する「KATACHI Business」では、単なる素材提供にとどまらず、お客様の課題解決に向けた総合的なソリューションを提供しております。 第2回コラム:「スーパーエンプラ加工の基礎知識!用途・種類・耐熱温度など」 スーパーエンプラ加工の基本から、その多様な種類やそれぞれの耐熱温度、そして半導体・電子部品業界をはじめとする幅広い分野での具体的な用途について詳しく解説します。 詳しくは、関連リンク先より弊社HPのKATACHIストーリーをご覧ください。

-

KATACHIストーリー コラム記事の掲載開始 第1回コラム:「樹脂板の種類は?加工しやすい素材・プラスチック板などを解説」

大塚化学は、「KATACHIストーリー コラム記事の掲載」を開始いたしました。 大塚化学は、これまで粉末状や液状等、部品になる前の「素材」を提供してきました。 これからは、素材の力と自社のコア技術を活用し、これまでの事業範囲を超えて新たな挑戦を続けています。 その一環として立ち上げられたのが「KATACHI Business」です。 単なる素材販売にとどまらず、素材を部品のような製品群としてKATACHIにすることで新たな価値を創造する。 この新たな取り組みを「KATACHI Business」と呼んでいます。 当社が推進する「KATACHI Business」では、単なる素材提供にとどまらず、お客様の課題解決に向けた総合的なソリューションを提供しております。 第1回コラム:「樹脂板の種類は?加工しやすい素材・プラスチック板などを解説」 記念すべき第1回では、樹脂板の基礎知識から実用的な加工技術まで、製造現場で役立つ情報を詳しく解説しております。 詳しくは、関連リンク先より弊社HPのKATACHIストーリーをご覧ください。